Vicor’s continual advances in power distribution architectures, conversion topologies and packaging technology keeps ahead in system efficiency and density, converting and managing power from the source to the point-of-load. Phil Davies, Vice President, Sales and Marketing, Vicor Corporation caught up with ELE Times discussing the competitive advantage in infrastructure, industrial and automotive applications to rapidly advance unique power system designs.

ELE Times: Discuss the power electronics portfolio in brief and what do you think is the current focus of the company?

Phil Davies: Vicor is focused on providing modular power solutions to power system designers that are easy to use, have the highest power density and efficiency. Vicor enables a faster time to design with an advantage of scalability if the end systems specifications change for the current project or the next project, which is common during product development. We are finding this approach to power systems design is very desirable for data centers, high performance computing, automotive, various industrial and defense/aerospace applications and in applications that are going through rapid change with higher power demands driving the move to higher power delivery voltages such as 48V.

ELE Times: EV/HEV are driving power module packaging innovations. What latest do you have in this sector?

Phil Davies: We introduced our ChiP (Converter housed in Package) power module packaging technology about seven years ago and have recently increased its performance with a new thermally adept design. By plating the surface with copper we are now able to offer chassis mount and surface mount options to the range of new ChiP’s we are developing and introducing. Power module packaging is critical to providing high density and high performance to our customers and we invest a great deal of our R&D budget in this area. We are constantly innovating with new materials and improving our integrated magnetics performance to drive up efficiencies and power capabilities in the smallest possible package.

ELE Times: The power module is key in the development of power converters and inverters. What growth do you see in the sector in the next 2-3 years?

Phil Davies: The markets for our power modules are in the multi billions of dollars. We estimate we are looking at a $7B market in our target segments. Our objective for the company is to achieve a 15% share in 5 years.

ELE Times: Increasing battery energy capacity enables longer driving range of electric cars while powerful electric motors enable quick acceleration. High electric power requirement as well as need for inverter downsizing brings challenges on the power module level. What technologies enables you to overcome the challenges?

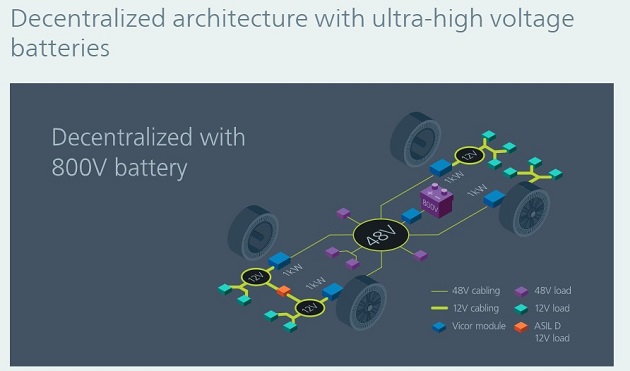

Phil Davies: In the DC to DC converter applications we are seeing higher battery voltages (up to 800V) with power levels in the 10KW to 40KW range depending on vehicle platform. Power delivery to the various loads in the vehicle is moving to 48V which is an SELV (Safety Extra Low Voltage) level. We are offering the industry solutions which comprise of a fixed ratio converter to down convert the high voltage battery to this SELV range followed by 48V to 12V non-isolated regulated converters. The majority of loads in vehicles remain at 12V but significant advantages can be had with distributing power with a 48V bus and saving on cable and connector size and weight. The reason we lead with our high voltage fixed ratio converters is that we have the highest power density technology in the industry to enable a small size and low weight solution at very high power levels. Our solution is 10 to 20 times smaller than the competition.

ELE Times: What are the challenges on standard power modules, and how can we actually optimize these standard power modules to be working well enough with silicon carbide?

Phil Davies: The challenges are to always be reducing the size and improving the efficiency of the power delivery solution. Because of our proprietary converter topologies and control systems we do not need GaN or silicon carbide switches. We can use standard MOSFET’s which have cost and performance benefits over these new technologies. Many customers ask us when we will use these new technologies and the answer is always when the time is right…which is not at the moment.

ELE Times: When we talk about higher switching frequencies of 40 kilohertz and above, that’s where we really should talk about full silicon carbide. Efficiency, modulation accuracy, and in the end, a reduction of size, and hopefully of cost. So what are actually the challenges when we talk about integration and power modules?

Phil Davies: Our topologies allow us to switch in the MHz range which enables us to reduce the size of our magnetics and passive components. It’s a very big competitive advantage. We have steadily increased our switching frequencies over the years and have some modules that switch at over 2 MHz, it really depends on the function and power levels.

ELE Times: Where the market is headed in terms of Automotive Power Electronics specifically Low Cost – High performance cooling technologies for next generation Hybrid Electric Vehicles (HEV), Plug-in Hybrid Electric Vehicles (PHEV) and Electric Vehicles?

Phil Davies: The focus of power module companies like Vicor should be on reducing the power losses in our converters so that thermal challenges are reduced. We have been able to cut losses by 25% every 2 to 3 years so we are on the right track. With lower power losses due to higher efficiencies, the size and therefore the cost of the power module can also be reduced. For very high power applications where cooling is necessary the power module should be easy to cool with a low profile and easy mounting to the cold plate surface. This is what our new SMChiP and CMChiP packages offer to the engineers.

ELE Times: What opportunities do you see for India post COVID-19 in terms of Manufacturing to be the second biggest industry while Multinational are disappointed with China?

Phil Davies: The opportunity for India has always been great. With such skilled and highly intelligent workforce availability the sky is the limit. With the right focus and investments the future is very bright for India.