As the world embraces the age of technology, semiconductors stand as the architects of the digital lives we live today. Semiconductors are the engines running silently behind everything from our smartphones and PCs to the AI assistants in our homes and even the noise-canceling headphones on our ears. Now, that same quiet power is stepping out of our pockets and onto our roads, initiating a second, parallel revolution in the automotive sector.

As we turn towards the automotive industry, we see a rise in the acceptance of electric and autonomous vehicles that has necessitated the use of around 1,000 to 3,500 individual chips or semiconductors in a single machine, transforming modern-day vehicles into moving computational giants. This isn’t just a trend; it’s a fundamental rewiring of the car. Asif Anwar, Executive Director of Automotive Market Analysis at TechInsights, validates this, stating that the “path to the SDV will be underpinned by the digitalization of the cockpit, vehicle connectivity, and ADAS capabilities,” with the vehicle’s core electronic architecture being the primary enabler. Features like the Advanced Driver Assistance System (ADAS) are no longer niche; they are central to the story of smart, connected vehicles on the roads. In markets like India, this is about delivering “premium, intelligent automotive experiences,” according to Savi Soin, President of Qualcomm India, who emphasizes that the country is moving beyond low-end models and embracing local innovation.

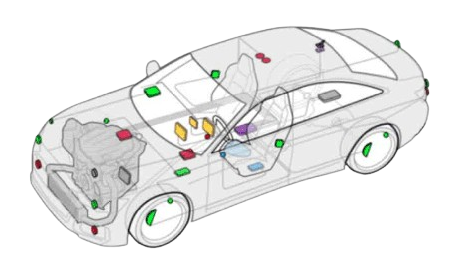

To understand this revolution—and the immense challenges engineers face—we must first dissect the new nervous system of the automobile: the array of specialized semiconductors that gives it intelligence.

The New Central Nervous System of Automotives

- The Brains: Central Compute System on Chips (SoC)

It is a single, centralized module comprising high-performance computing units that brings together various functions of a vehicle. These enable modern-day Software-Defined Vehicles (SDVs), where features are continuously enhanced through agile software updates throughout their lifecycle. This capability is what allows automakers to offer what Hisashi Takeuchi, MD & CEO of Maruti Suzuki India Ltd, describes as “affordable telematics and advanced infotainment systems,” by leveraging the power of a centralized SoC.

Some of the prominent SoCs include the Renesas R-Car Family, the Qualcomm Snapdragon Ride Flex SoC, and the STMicroelectronics Accordo and Stellar families. These powerful chips receive pre-processed data from all zonal gateways (regional data hubs) through sensors. Further, they run complex software (including the “Car OS” and AI algorithms) and make all critical decisions for functions like ADAS and infotainment, effectively controlling the car’s advanced operations; hence, it is called the Brain. The goal, according to executives like Vivek Bhan of Renesas, is to provide “end-to-end automotive-grade system solutions” that help carmakers “accelerate SDV development.”

- The Muscles: Power Semiconductors:

Power semiconductors are specialized devices designed to handle high voltage and large currents, enabling efficient control and conversion of electrical power. These are one of the most crucial components in the emerging segment of connected, electric, and autonomous vehicles. They are crucial components in electric motor drive systems, inverters, and on-board chargers for electric and hybrid vehicles.

Some of the prominent power semiconductors include IGBTs, MOSFETs (including silicon carbide (SiC) and gallium nitride (GaN) versions), and diodes. These are basically switches enabling the flow of power in the circuit.

These form the muscles of the automotives as they regulate and manage power to enable efficient and productive use of energy, hence impacting vehicle efficiency, range, and overall performance.

- The Senses: Sensors

Sensors are devices that detect and respond to changes in their environment by converting physical phenomena into measurable signals. These play a crucial role in monitoring and reporting different parameters, including engine performance, safety, and environmental conditions. These provide the critical data needed to make decisions in aspects like ADAS, ABS, and autonomous driving.

Some commonly used sensors in automobiles include the fuel temperature sensor, parking sensors, vehicle speed sensor, tire pressure monitoring system, and airbag sensors, among others.

These sensors, like lidar, radar, and cameras, sense the environment ranging from the engine to the roads, enabling critical functions like ADAS and autonomous driving, hence the name Senses. These are one of the crucial elements in modern automotive, as their collection enables the SoC to make decisions.

- The Reflexes and Nerves: MCUs and Connectivity

Microcontrollers are small, integrated circuits that function as miniature computers, designed to control specific tasks within electronic devices. While SoCs are the “brains” for complex tasks, MCUs are still embedded everywhere, managing smaller, more specific tasks (e.g., controlling a single window, managing a specific light, basic engine control units, and individual airbag deployment units).

Besides, the memory inside the automobiles enables them to store data from sensors and run applications while the vehicle’s communication with the cloud is enabled by dedicated communication chips or RF devices (5G, Wi-Fi, Bluetooth, and Ethernet transceivers). These are distinct from SoCs and sensors.

Apart from these, automobiles comprise analog ICs/PMICs for power regulation and signal conditioning.

Design Engineer’s Story: The Core Challenges

This increasing semiconductor composition naturally gives way to a plethora of challenges. As Vivek Bhan, Senior Vice President at Renesas, notes, the company’s latest platforms are designed specifically to “tackle the complex challenges the automotive industry faces today,” which range from hardware optimization to ensuring safety compliance. This sentiment highlights the core pain points of an engineer designing these systems.

Semiconductors are highly expensive and prone to degradation and performance issues as they enter the automotive sector. The computational giants produce a harsh environment, including high temperature, vibrations, and humidity, and come with an abundance of electric circuits. These factors together make the landscape extremely challenging for designing engineers. Some important challenges are listed below:

- Rough Automotive Environment: The engine environment in an automobile is generally rough owing to temperature, vibrations, and humidity. This scenario poses a significant threat, as high temperatures can lead to increased thermal noise, reduced carrier mobility, and even damage to the semiconductor material itself. Therefore, the performance of semiconductors heavily depends on conducive environmental conditions. Design engineers must manage these complex environmental needs through select materials and specific packaging techniques.

- Electromagnetic Interference: Semiconductors, being small in size, operating at high speed, and sensitive to voltage fluctuations, are highly prone to electromagnetic interference. This vulnerability can disrupt their operations and lead to the breakdown of the automotive system. This is extremely crucial for design engineers to resolve, as it could compromise the entire concept of connected vehicles.

- Hardware-Software Integration: Modern vehicles are increasingly software-defined, requiring seamless integration of complex hardware and software systems. Engineers must ensure that hardware and software components work together flawlessly, particularly with over-the-air (OTA) software updates.

- Supply-Chain-Related Risks: The automotive industry is heavily reliant on semiconductors, making it vulnerable to supply chain disruptions. Global shortages and geopolitical dependencies in chip fabrication can lead to production delays, increased costs, and even halted assembly lines.

- Design Complexity: The increasing complexity of automotive chip designs, driven by features like AI, raises development costs and verification challenges. Engineers need to constantly update their skills through R&D to address these challenges. This is where concepts like “Shift-Left innovations,” mentioned by industry leaders, become critical, allowing for earlier testing and validation in the design cycle. To solve this, Electronic Design Automation (EDA) tools are used to test everything from thermal analysis to signal integrity in complex chiplet-based designs.

- Safety and Compliance: Automotive systems, especially those related to safety-critical functions, require strict adherence to standards like ISO 26262 and ASIL-D. Engineers must ensure their systems meet these standards through rigorous testing and validation.

Conclusion

Ultimately, the story of modern-day vehicles is the story of human growth and triumphs. Behind every advanced safety system lies a design engineer navigating a formidable battleground. The challenges of taming heat, shielding circuits, and ensuring flawless hardware-software integration are the crucibles where modern automotive innovation is forged. While the vehicle on the road is a testament to the power of semiconductors, its success is a direct result of the designers who can solve these complex puzzles. The road ahead is clear: the most valuable component is not just the chip itself, but the human expertise required to master it. This is why tech leaders emphasize collaboration. As Savi Soin of Qualcomm notes, strategic partnerships with OEMs “empower the local ecosystem to lead the mobility revolution and leapfrog into a future defined by intelligent transportation,” concluding optimistically that “the road ahead is incredibly exciting and we’re just getting started.”