Vishay Intertechnology, Inc. introduced two new IHDM Automotive Grade edge-wound, through-hole inductors in the 1107 case size with soft saturation current to 422 A. Featuring a powdered iron alloy core technology, the Vishay Inductors Division’s IHDM-1107BBEV-2A and IHDM-1107BBEV-3A provide stable inductance and saturation over a demanding operating temperature range from -40 °C to +180 °C with low power losses and excellent heat dissipation.

The edge-wound coil of the devices released provides low DCR down to 0.22 mΩ, which minimizes losses and improves rated current performance for increased efficiency. Compared to competing ferrite-based solutions, the IHDM-1107BBEV-2A and IHDM-1107BBEV-3A offer 30 % higher rated current and 30 % higher saturation current levels at +125 °C. The inductors’ soft saturation provides a predictable inductance decrease with increasing current, independent of temperature.

With a high isolation voltage rating up to 350 V, the AEC-Q200 qualified devices are ideal for high current, high temperature power applications, including DC/DC converters, inverters, on-board chargers (OBC), domain control units (DCU), and filters for motor and switching noise suppression in internal combustion (ICE), hybrid (HEV), and full-electric (EV) vehicles. The inductors are available with a selection of two core materials for optimized performance depending on the application.

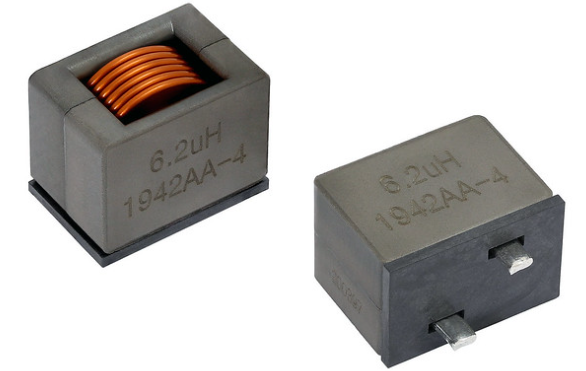

Standard terminals for the IHDM-1107BBEV-2A and IHDM-1107BBEV-3A are stripped and tinned for through-hole mounting. Vishay can customize the devices’ performance — including inductance, DCR, rated current, and voltage rating — upon request. Customizable mounting options include bare copper, surface-mount, and press fit. To reduce the risk of whisker growth, the inductors feature a hot-dipped tin plating. The devices are RoHS-compliant, halogen-free, and Vishay Green.