Art Pini, Digi Key

Portable and battery-powered devices are everywhere, and increasingly they’re taking control of everyday functions. A perfect example is those little robotic vacuums with motors for mechanical motion and directional control. While these may seem like an everyday function now, the electronics inside these little robots continue to push designers to the limits of small form factor, weight, and power efficiency, while packing a full processing toolbox.

It helps when much of the requisite electronics can be packed into one IC. That’s the case with Analog Devices’ MAX32672GTL+. This is a very small, ultra-low-power, highly integrated 32-bit microcontroller designed especially for battery-powered devices and wireless sensors. It has a powerful ARM Cortex M4 processor with a floating point unit (FPU), and it fits right into the device designs I mentioned due to its complex sensor processing and battery life optimization.

Applications for the MAX32672GTL+, as you might imagine, include motion/motor control, industrial sensors, and battery-powered medical devices. Its application can also be stretched to optical communication modules and secure radio modem controllers.

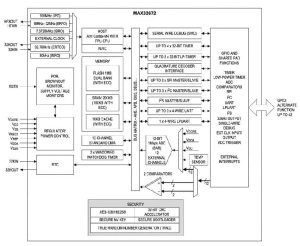

The functional block diagram of the MAX32672GTL+ reveals the versatility of this little powerhouse.

Starting with the memory, the MAX32672GTL+ integrates 1 megabyte (Mbyte) of flash memory and 200 kilobytes (Kbytes) of SRAM. The internal flash memory with error correction is used for non-volatile programs and data storage. It is organized in two equally sized banks to allow execute-while-write operations for live firmware updates.

The internal 200 Kbyte SRAM supports low-power retention of application information and related data. For enhanced system reliability, the SRAM can be configured as 160 Kbytes with single-error correction and double-error detection (SEC–DED) codes to protect memory devices from data corruption. Error correction coding is important: implemented on the entire flash, RAM, and cache, it ensures extremely reliable code execution in the presence of harsh environmental conditions.

For all-important power management and control, functions include multiple modes that provide a mix of high-performance and low-power consumption options. These include supply voltage and brownout monitors to ensure proper operation during power-down and power-up events, and unexpected supply transients.

The MAX32672GTL+ includes lots of I/O bandwidth with multiple serial I/O peripherals, including I2C, I2S, SPI, and UART. The bidirectional I2C interface instances can operate at transfer rates from 100 kilobits per second (kbps) to 3400 kbps. The SPI interfaces can operate at up to 50 megabits per second (Mbps) and support full-duplex operation in a four-wire configuration. The bidirectional I2S audio bus works with audio amplifiers and codecs.

Finally, the UART interfaces provide full-duplex asynchronous serial communications using either two or four-wire bus configurations with an independent baud rate generator. A low-power UART (LPUART) operates in the lowest-power sleep modes to facilitate wake-up activity without any loss of data.

Besides the serial interfaces, the peripheral mix includes up to 42 general-purpose I/O (GPIO) pins, up to four 32-bit timers, up to two low-power, 32-bit timers, and a 12-channel, 12-bit successive approximation register (SAR) analog-to-digital converter (ADC).

From a sheer hardware support point of view, the combination of the serial data links, I/O pins, and the ADC makes the MAX32672GTL+ a powerful controller for motors and other rotating machines which require substantial data processing.

Flexible support accelerates control and robotics designs

Without good support tools, hardware is limited. In the case of the MAX32672GTL+, that’s not an issue. Application-specific tools include the ability to monitor both analog and digital sensors to generate pulse width modulated signals and to decode data from quadrature shaft encoders. I really like tools that are aimed at motor control and robotics applications: they remove much of the complexity and make it a lot easier to get a design up and running.

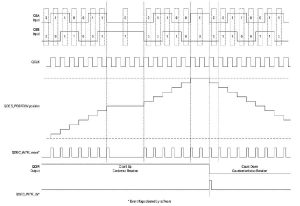

The quadrature decoder interface deciphers the shaft angle and rotational velocity of a rotating machine shaft based on the two-phase signal lines (QEA and QEB), and the index signal (QEI) from a shaft encoder. User-selected countdowns of X1, X2, or X4 are available to control the angular resolution of the decode operation. The rotation of the shaft is tracked on a 32-bit position counter (QDEC) along with specific events, such as reaching a preset position. The QDEC value indicates the current angular position of the shaft. Other outputs indicate motion, direction, and a change in rotational direction (Figure 2).

Figure 2: The quadrature inputs QEA and QEB—clocked by the quadrature clock—increment or decrement the QDEC counter depending on the direction of rotation. Output signals indicate movement (QDEC_INTFL), direction (QDIR), and a change in direction (QDEC_INTRL). (Image source: Analog Devices Inc.)

The MAX32672GTL+ incorporates Advanced Encryption Standard (AES) hardware to secure the device. AES keys are automatically generated by the software and stored in a dedicated flash region to protect against tampering. It includes a true random number generator (TRNG), providing random numbers for cryptographic seeds or strong encryption keys to ensure data privacy.

All of this processing power is contained in a small 40-pin TQFN-EP package that measures only 5 millimeters (mm) x 5 mm x 0.4 mm. The device has five different power modes offering great flexibility in operation while minimizing power consumption. Operating off a 1.1 volt supply, the microcontroller draws only 61.5 microamperes (mA) per megahertz (MHz) in active mode, up to its maximum clock rate of 100 MHz.

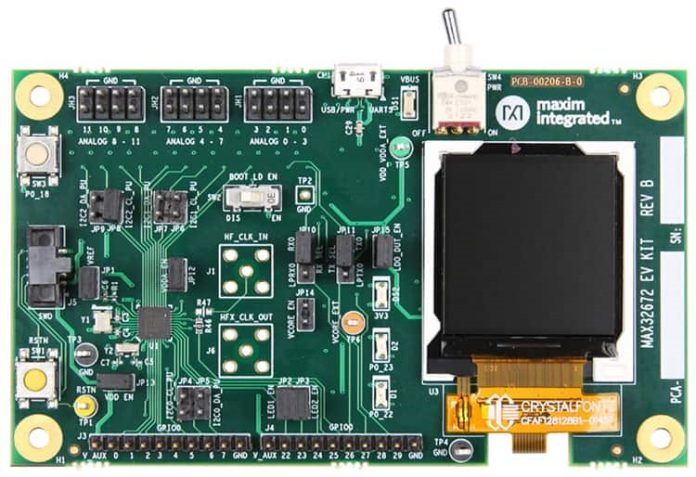

The Analog Devices MAX32672EVKIT# evaluation kit provides a platform for gauging the capabilities of the MAX32672GTL+ microcontroller (Figure 3). Anyone looking into using this microcontroller will find this evaluation board a great starting point for design.

Figure 3: The Analog Devices MAX32672EVKIT# evaluation kit has a MAX32672GTL+ with a pre-programmed demonstration and access to user-developed programs.

When initially powered up, the evaluation board executes a demonstration program. Beyond that, the evaluation board provides access via its internal I/O ports, and software development kits (SDKs) are available for writing your own programs.

Conclusion

The MAX32672GTL+ is a small, low-power, powerful, and flexible solution for motor/motion control, industrial sensors, and battery-powered medical devices: robotic vacuums are a perfect example. With its evaluation kit and rich tool support, I suspect there will be many other interesting designs based on it that will be proliferating soon. Let me know if you have one in mind.