Fluke Process Instruments has solved the measuring task for a chemical waste incineration plant. Hazardous wastes are combusted in a rotary kiln that turns at 4 to 6 revolutions per hour. Over time, the refractory brick protecting the kiln wall degrades and has to be replaced. This used to be done at regular intervals with a big safety margin to prevent serious damage to the incinerator or even leakage of hazardous materials.

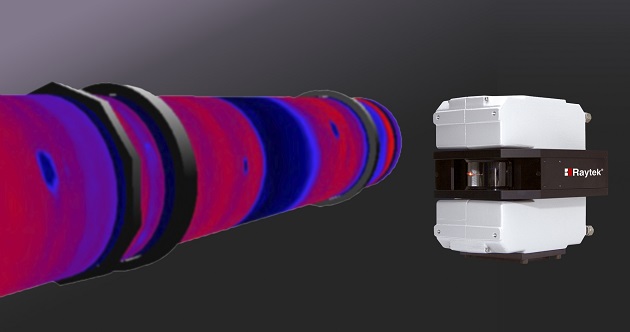

Fluke Process Instruments supplied a Raytek CS210 infrared line-scanning system that is able to synchronize thermal images at speeds as low as 2 revolutions per hour. It detects temperature deviations across the entire kiln shell and provides the plant operator with information about the state of the incinerator.

The kiln shell temperature ranges between 100 °C and 500 °C. Hotspots point to refractory loss or wear. The installation of the monitoring system has resulted in significant savings due to an extended operational life of the refractory and reduced downtimes.