Energy and Power Resources remain a very crucial factor for stable Economies. Increasing Pollution and Climate Change is majorly caused because of the rapid and increased usage of fuels like Petrol and Diesel. Major projections and forecast throughout the globe have always warned of serious and adverse reciprocations if the world continues to use these fuels. Batteries are the new normal. Battery in the Automotive Industry is the need of the hour and people around the globe are eagerly waiting for them. But the important factor which remains is the acceptance and understanding of the people in shifting their priorities from Fuels to Batteries. Other Factors like the Government and the Organisations should play an equal role in this implementation process too. The lack of an extensive charging infrastructure network concerns over battery range, cost of batteries and the environmental impact of disposing of lithium ion, lithium Ferro phosphate or lead-acid batteries have proven to be real bottlenecks. Ministry of Road Transport & Highways, Government of India has asked the EV industry to shift towards indigenous battery technologies. With electric vehicles (EVs) fast becoming the new reality, the need to emerge as pioneers in developing leading battery and power-train technologies is the priority. It is necessary to dedicate the coming years to rigorous research and development of such alternative battery technologies with the support of Institutions of Eminence (IoEs), industry, scientists, engineers, and the government.

Only shifting to the battery resources are not the option. Self-Reliance and Indigenous Production is really crucial as it will help reduce the cost of investment and manufacturing. India, today is one of the biggest importer and parasite of Batteries. What India today needs is an ecosystem stable and efficient enough to manufacture batteries and corresponding technology. Indian Market today has started analysing and understands the need for indigenous production so as to maintain its demand and stability across the sectors. A new study by CEEW Centre for Energy Finance has revealed that electric vehicles will be a $206 billion opportunity for India by 2030. But to make this happen, the country will need an estimated annual battery capacity of 158 GWh by FY30.

We are continuously looking at a time when a shift and an alternative to the lithium-ion batteries is really important. The dependence on China has reduced a lot with the pandemic and indigenous production of batteries is the new need of the hour. As far as the Lithium-Ion Batteries are concerned, Indian Companies are trying hard to manufacture the latter with much efficiency and low cost. Grinntech, an investor-backed start-up specialising in Lithium-Ion batteries for EVs and energy storage systems, announced the inauguration of its larger manufacturing plant in Chennai. Spread over a one-acre plot in Chennai’s Ambattur Industrial Estate, the unit has the capacity to produce 400 MWh per year of Lithium-Ion batteries suitable for two- and three-wheelers, farm tractors and light vehicles. The company has installed an optimal level of automation and has deployed contemporary quality control principles keeping in mind the quality expectations of our customers and our own productivity and safety targets.

In terms of export facility, Suzuki Motor Corporation, Toshiba Corporation and Denso Corporation has come up with an approach to convert their manufacturing facility cell in Gujarat for lithium-ion export hub. The joint venture, TDS Lithium-ion Battery Pvt. Ltd is also expected to receive sops under the government’s production linked incentive (PLI) scheme for advanced chemistry cell (ACC) manufacturing in India.

Mumbai-based electric vehicle and energy storage company Gegadyne has raised $5 Mn in strategic investment from electrical appliances giant V-Guard. The proposed battery is expected to charge from 0 to 100% in around 15 minutes. These are just initial approaches, we have many more alternatives and evolution to witness.

This article has tried to highlight some of the biggest changes in the Indian market and, how encouraging would be the new era of inborn production and initiatives.

A Made in India EV Initiative

Delhi-based iPower Battery’s energy solutions are popular among EV startups The company’s energy solutions are popular among EV startups as they are swappable and modular, and come with advanced tracking, geo-fencing, remote monitoring, battery immobilisation, active and passive cooling and control, etc.

The company provides tailor-made Lithium Batteries for specific needs and are manufactured with best in class NMC (Nickel Manganese Cobalt) and LFP (Lithium Iron Phosphate) cells with the battery depicting features like the intelligent swapping with heat dissipation. The company also believes in empowering mobility space in India with efficient batteries, chargers and different allied products with a primary vision to become a consistent energy provider for ecosystems of the EVs catering to almost all segments of automotive. iPower is expected to play a major role in catalysing this revolution, and it can happen if the company focuses on improving its products rather than focusing on competitors.

Graphene for the New Alternative

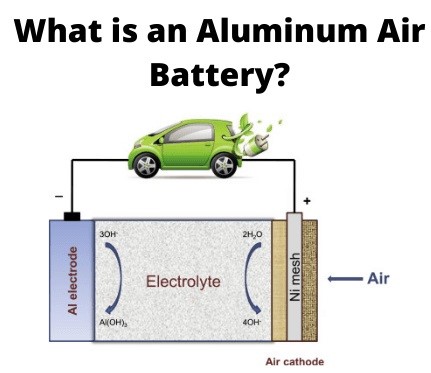

Lithium-ion battery and aluminium fuel cells (AFC) majorly differ in their storage factor, where the former is a storage device that requires regular charging while the latter is a pure power generation device. In terms of efficiency, the aluminium fuel cells are more useful as there is no need to charge for long hours and also offers a good range of above 1000kms contradictory to the conventional lithium-ion batteries which offer around 250kms range.

Lithium-ion battery and aluminium fuel cells (AFC) majorly differ in their storage factor, where the former is a storage device that requires regular charging while the latter is a pure power generation device. In terms of efficiency, the aluminium fuel cells are more useful as there is no need to charge for long hours and also offers a good range of above 1000kms contradictory to the conventional lithium-ion batteries which offer around 250kms range.

A Bengaluru-based nanotechnology company specialising in Graphene called Log 9 Materials have developed their own brand of aluminium fuel cells (AFCs) that offer five times the range than an average lithium-ion battery can offer, costs 30 per cent cheaper, is easier to use and doesn’t require the hassle of constantly recharging it. An alternate to the Lithium batteries has always been on the talks. This battery developed is literally something trying to reshape the energy efficiency in automotive and corresponding sectors and also aims at providing a range of over 2000kms. These Fuel cells are very much affordable in terms of price as compared to the Lithium-Ion Batteries and other counterparts, whereas also offering almost five times the range and minimal electricity consumption. Graphene and Simple Aluminium Water are the main constituents, which are easily accessible and cheaper too.

Ever wondered what a crop residue could do?

The concept of Waste to Wonders have been successfully accomplished and it is something which the Industry experts would think twice before even believing and investing in it. The technology of generating energy resources from waste is not new in the world, but it is equally relevant that implementing these technologies for the automotive sector would definitely produce fruitful results to the economy as well as the freight system of the country. A Bengaluru based Company called Nexus Power has achieved this dream of creating energy from crop residues.

This is purely a start to the sustainable impact in the EV space aiming at a very holistic approach. The Company also believes that in order to promote the electric vehicle segment, perfect battery and energy resources has to be achieved first. The process of generation involves the procurement of unburnt crop remains and transforming them to rechargeable energy storage cells with a unique extraction and filtrations process. All the structural elements of this eco-friendly, sustainable and lithium-ion free cell, the cathode, anode and electrolyte was built with the nanodot proteins derived from crop-residue. These type of energy storage cells also help in IoT and AI-based sensor-enabled battery pack.

Economically, this can prove to be very cost-efficient as the raw materials than would be available at very low-cost thereby reducing the price of the end product. Procurement of crop waste helps farmers earn an additional income of Rs 25,000 for every 100 batteries. Also, the patented technological innovations will eradicate seven billion tonnes of carbon dioxide from the atmosphere by the next century, making it suitably environment friendly.

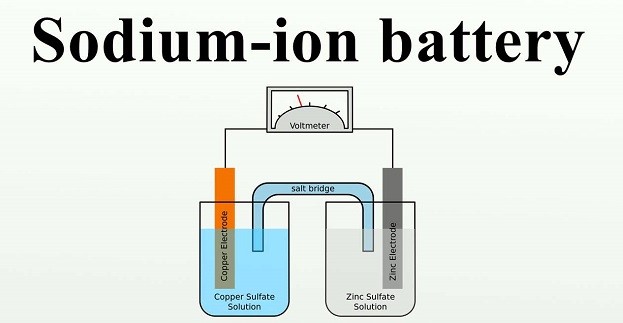

What can Sodium-ion batteries do? Is it a valid alternative to Lithium-ion batteries!

Sodium (Na)-ion batteries (NIBs) have great potential to represent the next generation low cost and environmentally friendly energy storage solution. The diverse key performance indicators required by different applications and the market diversification is the driving force pushing the Na-ion technology closer to the market. Scientists from the University of Warwick combined their knowledge and expertise to assess the current status of the Na-ion technology from materials to cell development, offering a realistic comparison of the key performance indicators.

LIBs play a primary role in the transition to a low carbon economy. However, as the market rapidly expands, the environmental and social challenges associated with the mass production of LIBs is triggering large attention toward the search for alternative energy storage solutions based on materials that can be sourced in a sustainable and responsible way. In this scenario, NIBs represent an alternative low cost, sustainable and more environmentally friendly energy storage technology. Na- based batteries offer a combination of attractive properties. They are low cost, use sustainable precursors and have secure raw material supplies. In addition, they are considered as a drop-in technology that could benefit from the already existing Li-ion batteries manufacturing facilities.

Na-based batteries come in different forms, such as Na-ion, Na-all-solid-state-batteries, NaO2 and Na/S. While the last ones are seen as disruptive future technologies, the Na-ion technology represent an attractive technology almost ready to challenge the Li-ion batteries in specific applications. Performance metrics are of utmost importance for the SIB technology to ensure a competitive cost and find a place in the market. In this work, the most promising electrode materials and electrolyte systems have been reviewed and performance metrics from the academic literature have been used to extrapolate full sodium-ion cells performance indicators.

Technological improvements are needed to increase the performance especially in terms of energy density. Extremely encouraging results have been achieved for the Na-ion technology in a very short time when compared to the Li-ion technology. Technological improvement will be achieved by cell component fabrication/assembly optimization, as occurred in the last thirty years for LIB technology.

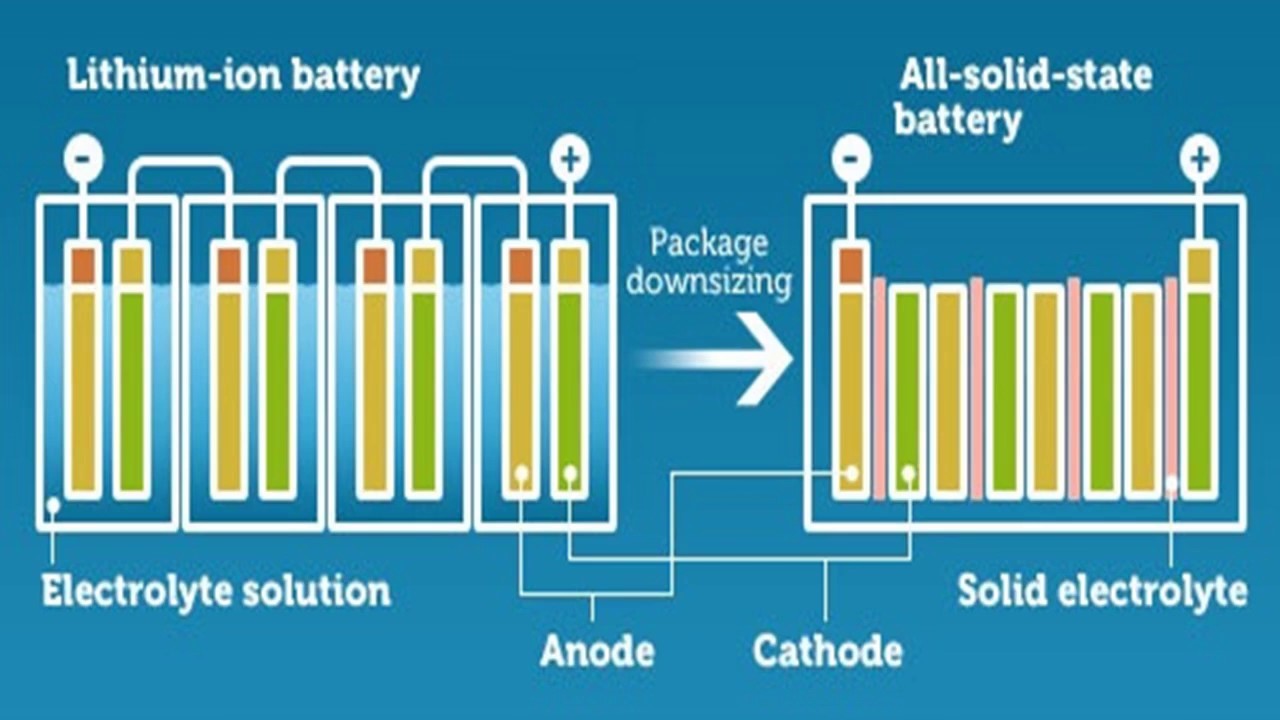

The New Solid-State Lithium Battery

Despite the advancements in lithium-ion batteries in the last decade, the batteries still lack the range that would make them a viable alternative to internal combustion engines. QuantumScape, one of the leading developers of solid-state lithium metal batteries has addressed the main issues holding back the broader adoption of solid-state batteries. It addresses the issues of charge time, cycle life, safety, and operating temperature that are of critical importance for EVs’ growth. A solid-state lithium state battery has been in development for quite some time, and researchers worldwide have been working on it for the past decade. The company’s latest offering is designed to increase the range by 80% compared to ordinary lithium-ion batteries.

Solid-state separators can work at high rates of power, which enables a 15-minute charge to 80% capacity, which is a considerable improvement over conventional lithium-ion batteries. The results also point out the fact, the QuantumScape’s battery is capable of lasting for long distances, and the battery is designed to operate at varying temperatures, with the results showing operations at even -30 degrees Celsius. This Technology eliminates the carbon or silicon anode, and the design increases the energy density because it uses no excess lithium on the anode and also eliminates the side reaction between the liquid electrolyte and the carbon in conventional lithium-ion cells’ anode. The technology is designed to last hundreds of thousands of miles of driving. The solid-state separator is non-combustible and isolates the anode from the cathode even at very high temperatures-much higher than conventional organic separators.

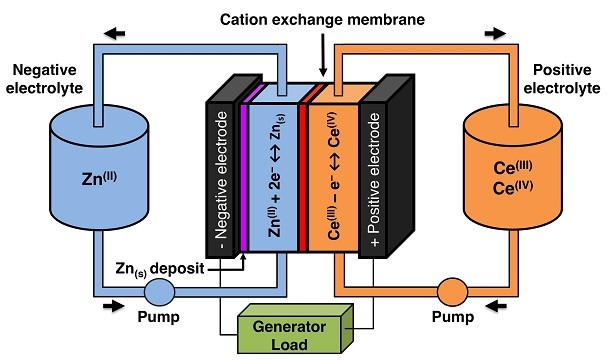

Zinc-Based Batteries: No to import of raw materials

The Indian Market was at a time continuously dependent of Lead Acid Batteries which proved to be cheaper and also low on efficiency, then the market selectively moved to Lithium-ion batteries, which was efficient but still required Lithium and Cobalt to be imported from different countries. With the Pandemic affecting almost all the logistic and freight sector of the globe, it was equally relevant and important to find an alternative and thereby the concept of zinc-based battery models took importance.

ZincGel, battery chemistry invented by IIT Kanpur-incubated startup Offgrid Energy Labs, aims to make a difference. ZincGel batteries are zinc-based and utilize materials readily available in India. Most importantly, they are non-toxic, in contrast to lithium-ion and lead-acid. The current battery landscape has technologies such as lithium-ion, which is quite efficient but expensive, and lead-acid, which is available at low cost but highly inefficient. Both options are ecologically unsustainable, thereby reducing the widespread usage of these batteries in renewable energy, utility and mobility applications. ZincGel, a solvent-less electrolyte derived from non-toxic salts that are new in terms of their utilization in battery chemistry but otherwise commonly used in agriculture and the animal feed industry. The electrolyte is temperature stable and non-flammable, offering resilience and safety for energy storage. Unlike lithium-ion cells, ZincGel batteries do not need clean and dry rooms. This can lower capital expenditure by up to 35 percent and also, lead acid manufacturers can make ZincGel batteries easily with existing equipment.

Aluminium is not just a raw material now, rather a crucial source of energy

Even though, aluminium was considered to be an ideal part of the automotive industry, it was only used in the manufacturing process as a raw material. Today, the role of the aluminium stands precisely in the energy making sector too in the electric vehicle segment. The automotive giant Mahindra’s electric venture Mahindra Electric is considering a new form of energy source metal-air batteries on its three wheeler segment. These batteries are significantly expected to match the performance of traditional fuel and would require only 5 minutes to refill too. This initiative require light infrastructure, are weather proof and most important affordable.

A recent meeting between the Indian Ambassador to Israel, Sanjeev Kumar Singla reviewed the progress on the MoU signed by IOCL (Indian Oil Corporation Ltd) and Phinergy (an Israeli start-up company specializing in hybrid lithium-ion and aluminium-air/zinc-air battery systems)

An update on this front is that the partners have announced that they have been progressing well and in fact, have onboarded Mahindra Electric to test out the metal-air batteries. IOCL has helped to develop the e-mobility product by Phinergy for Mahindra Electric. Phinergy’s aluminium-air technology is said to enable easy storage, transport and discharging of clean energy around the world. Its aluminium-air systems produce energy by combining aluminium, oxygen, and water.

Towards a Sustainable Future Production

The Road ahead for India is less dependent in terms of purchasing raw material and resources. Indigenous production post-Covid-19 has to be taken seriously considering the countries growth model and the surge to achieve above 5 trillion economy GDP. Countries around the globe are looking at India as a golden bird for investment, manufacturing and research. French utility major EDF Energy is exploring business opportunities in the Indian market for electric vehicle charging infrastructure, hydrogen fuel and battery storage technologies, in line with its plans for the post-Covid-19 economy. EDF is to build six reactors, each with a capacity of 1,650 MW each at the proposed plant near Ratnagiri in Maharashtra. When operational, it will be the largest nuclear generation park in the world with a capacity of 9,900 MW. At the same time, battery cell quality including capacity and battery life should be sustainably covered by a production and lifecycle control solution and supported by an in-line inspection system. This solution must consider all steps, from production through to use and recycling. By implementing these technologies, companies take an important step towards the sustainable factory and battery production of the future for the goal of self-reliance and no dependence.

By Mannu Mathew | Sub Editor | ELE Times

Related Links: Explore a new world of Mobility