Researchers at North Carolina State University have developed a technique for converting positively charged (p-type) reduced graphene oxide (rGO) into negatively charged (n-type) rGO, creating a layered material that can be used to develop rGO-based transistors for use in electronic devices.

“Graphene is extremely conductive, but is not a semiconductor; graphene oxide has a bandgap like a semiconductor, but does not conduct well at all – so we created rGO,” says Jay Narayan, the John C. Fan Distinguished Chair Professor of Materials Science and Engineering at NC State and corresponding author of a paper describing the work. “But rGO is p-type, and we needed to find a way to make n-type rGO. And now we have it for next-generation, two-dimensional electronic devices.”

Specifically, Narayan and Anagh Bhaumik – a Ph.D. student in his lab – demonstrated two things in this study. First, they were able to integrate rGO onto sapphire and silicon wafers – across the entire wafer.

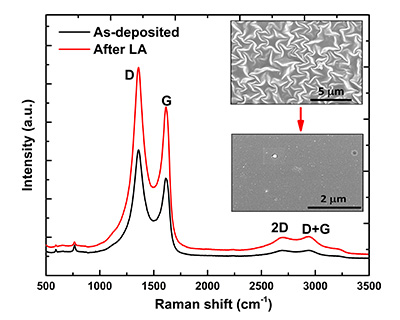

Second, the researchers used high-powered laser pulses to disrupt chemical groups at regular intervals across the wafer. This disruption moved electrons from one group to another, effectively converting p-type rGO to n-type rGO. The entire process is done at room temperature and pressure using high-power nanosecond laser pulses, and is completed in less than one-fifth of a microsecond. The laser radiation annealing provides a high degree of spatial and depth control for creating the n-type regions needed to create p-n junction-based two-dimensional electronic devices.

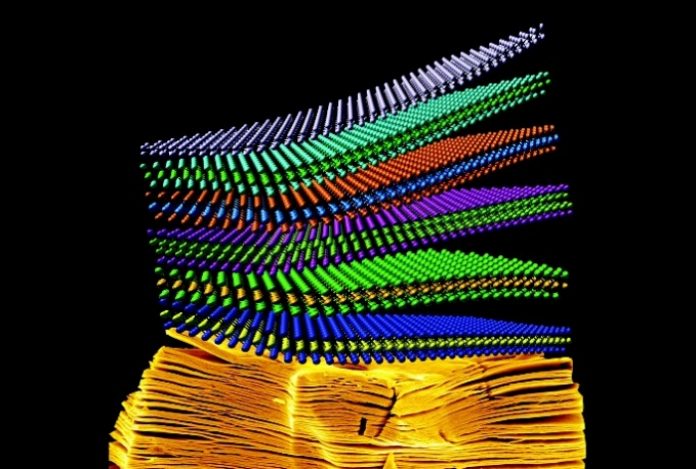

The end result is a wafer with a layer of n-type rGO on the surface and a layer of p-type rGO underneath.

This is critical, because the p-n junction, where the two types meet, is what makes the material useful for transistor applications.