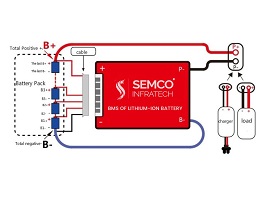

Whether it is an electric vehicle, an energy storage power station, or a base station power supply, the battery is an energy storage element. The perception, decision-making, and execution of the battery constitute the whole energy storage control system. In the article, the role of a BMS is highlighted as an extremely important sensor, which makes BMS the core foundation of the energy storage system.

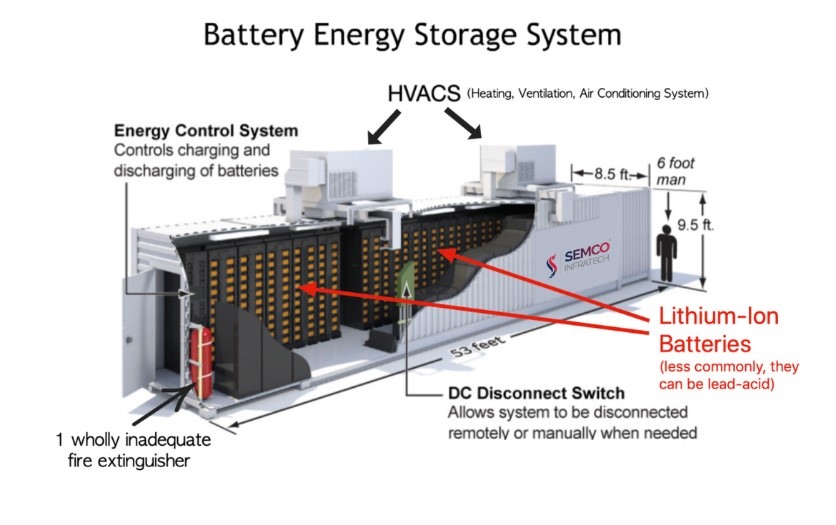

For general energy storage systems, in a limited space, the energy storage capacity of the battery pack is often MWh, and the conversion power is hundreds of KW to MW, which requires a large number of batteries to be connected in series. An energy storage unit is often composed of multiple sets of battery clusters in parallel into battery arrays and involves the coordination of multiple control units, system topology, and complex system wiring. It makes the energy storage system characterized by high DC side voltage (up to more than 1500V), high power (hundreds of kilowatts or megawatts), a large number of batteries, harsh electromagnetic environment, serious interference, huge data, and complex control. Extremely high requirements are put forward for BMS circuit principle and layout wiring design, anti-interference EMC design, data processing ability, response speed, etc. At the same time, it also puts forward high requirements for the layout, wiring, grounding, and other design of the entire energy storage system. It is necessary to consider not only the safety of wiring but also the coupling and shielding of signals.

Due to the characteristics of deep charging and discharging of the energy storage system, the consistency of cell capacity in the battery cluster at the end of charge and discharge will affect the available capacity of the energy storage system and reduce the efficiency of the energy storage system. To ensure the consistency of monomer battery performance in the battery pack, energy storage BMS must be required to have strong battery balance management ability. Therefore, the energy storage system generally requires active balancing technology, and the equilibrium current is generally 0.5 and 5A, to quickly and effectively compensate for the differences caused by the primary charging and discharge cycle battery packs, eliminate the differences, and ensure that the available capacity of the battery system is maximized. For 280Ah batteries, the difference of 1% is 2.8Ah, passive equilibrium is difficult to work.

To ensure the service life of the battery, temperature control is very important, and the thermal management of the system must be carefully designed. Especially for energy storage systems in frequency modulation and peak regulation applications, due to the high-powered charging and discharge current, the battery will be seriously heated and uneven, and the battery performance attenuated quickly, finally shortening the battery service life. Thermal management design includes the thermal design of the battery module, the system heat dissipation air duct, the BMS thermal management control strategy, etc. The liquid cooling system can better realize battery thermal management. Similarly, abnormal battery temperature is often a precursor to deterioration of battery performance and thermal runaway, which is extremely important for battery temperature monitoring. To avoid blind spots in battery abnormal temperature monitoring, it is often necessary to monitor the battery temperature to the requirements of each cell.

When multiple batteries are used in parallel (or battery stack maintenance), the parallel control strategy of the battery pack must also be considered to prevent the circulation caused by the voltage difference between batteries, as well as the balanced maintenance between different battery clusters.

Due to the complexity of the system, multiple data interfaces, and a large number of data access, BMS control units are required to have complex and negotiated processing power and response speed and put forward high requirements for processor, software architecture, and code quality. Such as IEC61850 access protocol, data storage, fault tracing, system redundancy, etc. Generally, it requires at least 3 to 5 years of data preservation capacity, and if the data preservation needs of the whole life cycle are to be met, it should have at least more than 15 years of data preservation capacity. In FM applications, high requirements are also put forward for data response speed. At present, it takes about 10s for the whole container battery data to be fully delivered once, which can’t meet the needs of FM applications at all.

Because the energy storage system has extremely high requirements for safety and reliability, it also requires high reliability, system fault tolerance, and functional safety requirements for BMS. The design life of the energy storage system is generally 15 years, and the corresponding life requirement for energy storage BMS is 15 years, but at present, the relevant standards of energy storage BMS do not describe the reliability index. From the requirements of the energy storage system, it is recommended to be MTBF (Mean Time Between Failure) = 105, or the annual failure rate can be defined as W100^500ppm Similarly, energy storage BMS should also meet the requirements of ULS-61508 to ensure the system safety of BMS in a faulty state.

The safety of energy storage systems is the pain point and difficulty in the development of the energy storage industry. Battery safety status analysis and early warning are extremely important requirements for BMS.

Generally speaking, the application scenario of the car puts forward environmental requirements such as wide temperature range, temperature transient, vibration, waterproofing, etc. for BMS, strict and standardized protocols and strategies, extremely high safety requirements (IS026262), extremely high-reliability requirements (less than 100ppm), and standardized requirements (IATF169). And so on, while the energy system is relatively small. The system is less complex. The energy storage system is more complex and larger, the charging and discharge depth is deeper, and the life cycle is longer. Therefore, it is necessary to specially design and develop energy storage BMS according to the above differences. For the battery array architecture of the energy storage system, the corresponding BMS also needs to be managed for the three-level architecture of the cell, battery cluster, and battery array design to clarify the relationship at all levels and ensure the safe and reliable operation of the system.

Courtesy: Semco Infratech