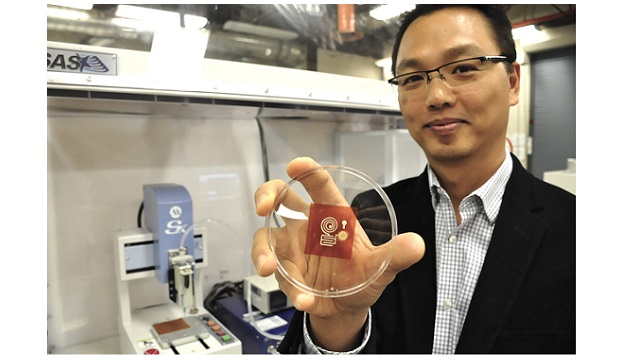

An eco-friendly 3D printable solution for producing wireless Internet of Things sensors, is to be developed by the collaboration of Simon Fraser University’s Mechatronic System professor Woo Soo Kim and Swiss researchers. The research team is using a wood-derived cellulose material to replace the plastics and polymeric materials currently used in electronics. The solution could be used and disposed without causing any contamination in the environment.

The research team’s discovery of involving the use of a wood-derived cellulose material, is led by SFU professor Woo Soo Kim. Additionally, 3D printing can give flexibility to add or embed functions onto 3D shapes or textiles, creating greater functionality.

“Our eco-friendly 3D printed cellulose sensors can wirelessly transmit data during their life, and then can be disposed without concern of environmental contamination,” says Kim, a professor in the School of Mechatronic Systems Engineering at SFU’s Surrey campus. The research is being carried out at PowerTech Labs in Surrey, which houses several state-of-the-art 3D printers used by researchers.

“This development will help to advance green electronics. For example, the waste from printed circuit boards is a hazardous source of contamination to the environment. If we are able to change the plastics in PCB to cellulose composite materials, recycling of metal components on the board could be collected in a much easier way.”

He is also collaborating with a team of South Korean researchers from the Daegu Gyeongbuk Institute of Science and Technology’s (DGIST)’s department of Robotics Engineering, and PROTEM Co Inc, a technology-based company, for the development of printable conductive ink materials.

In this second project, researchers have developed a new breakthrough in the embossing process technology, one that can freely imprint fine circuit patterns on flexible polymer substrate, a necessary component of electronic products.

Embossing technology is applied for the mass imprinting of precise patterns at a low unit cost. However, Kim says it can only imprint circuit patterns that are imprinted beforehand on the pattern stamp, and the entire, costly stamp must be changed to put in different patterns.

The team succeeded in developing a precise location control system that can imprint patterns directly, resulting in a new process technology. This will have widespread implications for use in semiconductor processes, wearable devices and the display industry.