Phil Kinner, Head of the Conformal Coatings Division at Electrolube, explains how modern, carefully formulated conformal coatings are helping automotive electronics manufacturers to deliver high-reliability, long-life products for a particularly demanding customer base.

While the value of the electronic systems in a modern vehicle typically exceeds 20% of the total vehicle cost, many estimate that this value will exceed 35% within the next 5 year period. With the increased adoption of electronic vehicles and the development of the Internet of Things, which has brought us driverless cars like those being tested by Google in California, and BMW on the roads of Bavaria, the future of this industry is starkly different to that of the 1970s when electronic fuel injection systems were first introduced to mainstream production.

The proliferation of automotive electronics has been enabled by the development of powerful networked controllers and low-cost sensors, as well as the development of low-cost, high reliability electronic systems that have seen engine management, infotainment, and passenger comfort and safety applications becoming standard equipment in most modern automobiles.

It is not uncommon for modern new vehicles to be supplied with 5 and even 7 year warranties and this is challenging component suppliers to develop new designs that deliver long term reliability at an acceptable cost. Automotive electronic systems are subject to temperature extremes, high humidity and condensation, and are increasingly exposed to corrosive gases. And with the growth of electric vehicles, where much higher voltages are the norm, increased dielectric protection is required to enable designs to be sufficiently dense to meet size and weight constraints.

The increased sophistication of these electronic systems often means they are more sensitive to contamination and adverse external environmental conditions. Moreover, as automotive electronic systems rely increasingly on their interconnection, failure in one assembly can compromise the operation of another. Unlike aerospace applications where two or three layers of redundancy may be built into these systems, automotive designs typically must work first time, every time, throughout the life of the product.

Circuit protection using conformal coatings

Conformal coatings are thin, protective polymeric coatings that are often applied to electronic circuit boards or assemblies to provide the required environmental protection without excessive cost or weight penalties. For the automotive industry, conformal coating applications are either ‘in-cabin’ (electronics systems located within the passenger compartment) or ‘under-hood’ (electronics in close proximity to the engine). Such distinct categories make it convenient to discuss the main requirements of each; however, with increased sophistication and the move towards multi-function assemblies, these traditional environments continue to merge, while the drive to higher power electronics in electric cars blurs the lines still further.

Electronic sensors and systems situated in the passenger cabin essentially occupy the same space as the vehicle occupants. In the winter, that can mean extreme cold and the tendency towards a condensing atmosphere, while in the summer, the tendency is towards a warm and humid atmosphere. Both condensation and high humidity challenge the reliability of electronics as they promote corrosion. In addition, electronics may be exposed to atmospheric pollutants such as cleaning solutions, liquid splashes and so on, and any one of these factors may pose a potential reliability risk, especially in association with humidity and condensation.

Electronic sensors and systems situated in the passenger cabin essentially occupy the same space as the vehicle occupants. In the winter, that can mean extreme cold and the tendency towards a condensing atmosphere, while in the summer, the tendency is towards a warm and humid atmosphere. Both condensation and high humidity challenge the reliability of electronics as they promote corrosion. In addition, electronics may be exposed to atmospheric pollutants such as cleaning solutions, liquid splashes and so on, and any one of these factors may pose a potential reliability risk, especially in association with humidity and condensation.

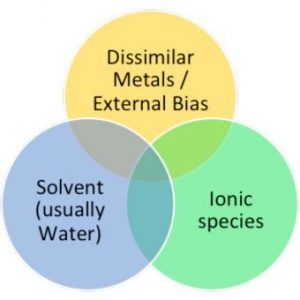

Corrosion is a complicated electro-chemical process, with a variety of potential mechanisms and causes, and any detailed description is beyond the scope of this article. However, in the vast majority of cases, there are three conditions that must be met in order for corrosion to take place:

- Intrinsically electrochemically dissimilar metals (e.g. gold/silver and nickel/tin) are present or an anode and cathode are created by application of applied bias.

- The presence of an ionic species (usually salts, halides, hydroxides, etc).

- Mono-layers of condensed water are present that dissolve the ionic species, resulting in an electrolyte solution.

In order to prevent the possibility of corrosion, it is necessary to remove one of the pre-requisite conditions.

The choice of metals is limited to those used in the solder and solder finish chemistries, which are dissimilar, and there will always be areas of potential difference due to the nature of an electronic assembly. Cleaning can help remove ionic species, but cannot prevent the re-deposition of ionic species from the operating environment.

Conformal coatings help prevent the formation of electrolytic solutions by acting as moisture barriers. The coating needs to be a good barrier against moisture and must have good adhesion to the substrate to prevent delamination. Once the coating is delaminated, moisture can eventually collect in this ‘pocket’ and form an electrolytic solution with any pre-existing ionic contamination. This is why cleaning prior to conformal coating is recommended to provide a powerful synergistic elimination of two of the three pre-requisite conditions for corrosion.

Given the relatively benign operating environments experienced by ‘in cabin’ electronics, acrylic conformal coatings have historically dominated this segment, offering good all round properties, especially against high humidity and spills and splashes.

Under-hood electronics, by dint of their location, face greater environmental challenges than ‘in cabin’ electronics. This environment is much less controlled, with higher maximum operating temperatures and far more opportunities for contamination by fuels, oils, cleaning fluids, corrosive gases, metal particulates and salt-water slush spray from treated road surfaces. Clearly, ‘under-hood’ and other non-cabin electronic assemblies suffer much tougher environmental conditions and thus require the greater levels of protection provided by a new type of conformal coating.

Protective coatings: the next generation

Coatings for electronic assemblies destined for under-hood and other non-cabin applications are required to be extremely resistant to wet conditions, have excellent chemical resistance, be highly flexible to survive thermal excursions and thermal shock, and be able to survive the much higher operating temperatures.

To counter these challenges, Electrolube has developed a new range of highly durable, solvent-free, modified polyurethane conformal coatings, which can be applied more thickly than regular conformal coatings and which cure within 10 minutes at 80°C, re-using existing thermal curing ovens often used in solvent-based processes.

Moisture resistance

‘Sharp-edge coverage’ – the ability of a coating to completely and reliably cover device leads, solder joints and other metal surfaces to prevent susceptibility to corrosion – is a long-standing, well known issue that has recently been highlighted within the IPC5-22ARR J-STD-001/Conformal Coating Material & Application Industry Assessment.

To demonstrate the importance of edge coverage and protection from liquid water in the form of condensation, the UK’s National Physical Laboratory (NPL) is currently working on the development of a controlled condensation test. NPL researchers have shown that at 40°C and 93%RH, a temperature differential of just 1.5°C can lead to the formation of moisture that is sufficient to reduce the surface insulation resistance (SIR) of a copper coupon from TΩ to 1MΩ (the limit of detection).

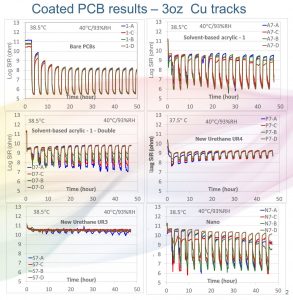

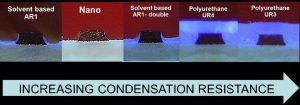

Referring to figure 2, the data (courtesy of NPL) clearly show a significant drop in the SIR value of an uncoated assembly; limited protection by both the nano-coating and the single-coated acrylic; improved protection from the double-coated acrylic; both the new urethane materials providing improved protection with UR3, in particular, showing outstanding protective capabilities against condensing water.

This can be explained in part by thickness and coverage, although the particular chemistry of the formulation also plays a significant role, as explained by the significant difference in performance between UR4 and UR3, even though the applied thicknesses (c. 150µm) are similar, as shown in the cross-section in figure 3 below.

Thermal shock resistance

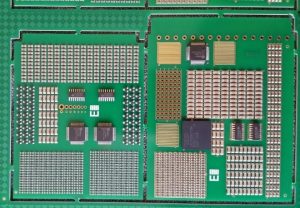

Automobile electronics are usually required to work between -40°C and 125°C, with rapid transitions between the temperature extremes. The Electrolube SIR test coupon shown in figure 4 was designed with a number of components laid out in a difficult configuration to better simulate a production assembly. Coupons were selectively coated with polyurethanes UR3 and UR4 at a target thickness of 250µm and subjected to 1000 air-to-air thermal shock cycles, at the temperature extremes previously indicated, with a rate of temperature change in excess of 40°C/min.

These coupons were visually inspected at 20X magnification for evidence of cracking, delamination and solder joint or component damage. After 1000 cycles, UR3 showed some signs of surface cracking and discoloration, but did not expose any metal surfaces and did not propagate to the surface of the board, whereas UR4 showed almost no change in appearance.

These coupons were visually inspected at 20X magnification for evidence of cracking, delamination and solder joint or component damage. After 1000 cycles, UR3 showed some signs of surface cracking and discoloration, but did not expose any metal surfaces and did not propagate to the surface of the board, whereas UR4 showed almost no change in appearance.

Salt-mist resistance

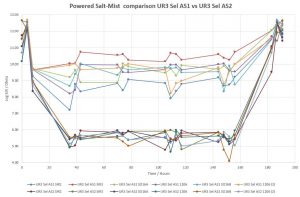

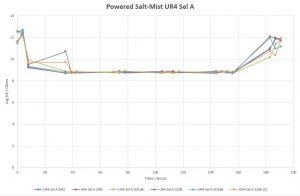

In order to assess the protection provided under salt-mist conditions (simulating winter driving conditions), the test coupons shown in figure 4, previously exposed to the 1000 thermal shock cycles were subjected to a 196-hour salt-mist test (5% NaCl solution). The coupons were continuously powered at 50V for the duration of the test and the insulation resistance was measured at periodic intervals throughout the test.

As shown in figure 5 below, both materials performed well, providing excellent protection against a salt-mist environment, although UR3 delivered a higher overall degree of insulation resistance, in line with the results from NPL’s condensation test.

Summary

In order to meet the demands of the automotive industry for greater electronics reliability under increasingly adverse conditions, Electrolube has developed a range of solvent-free, higher performance protective coatings that can be applied at greater thicknesses to overcome common application defects while improving sharp-edge coverage.

These materials have demonstrated significant performance improvements on model PCB test assemblies, in terms of resistance to thermal shock, condensing and salt-mist environments, over that of traditional conformal coatings, ultra-thin coatings or even UV curable materials.