With the advancement of internet technologies (IT), Internet of things (IoT), and Industrial IoT (IIOT) it seems that the age-old adage “experiments and experience make the man perfect” is applicable to machines as well. The realization that experiments and experience make machines wiser and productive, has led to the invention of ‘Machine Learning’. This technique enables machines with sensors to experience and learn the same way human beings do. It is coupled with an analytics engine which processes and learns from the experience just like humans do with their brains.

In order to implement a smarter workplace, you need to implement IIoT and Machine Learning (ML) technologies to the existing as well as new systems in your factory floor or workplace. This will enable the machines to have ears and eyes in the form of sensors or data collecting modules. This data can then be collected to perform edge analytics or filtering to ensure that the machines are collecting relevant data. The machine can send the collected relevant data through a channel to the memory (cloud) using IOT where the analytics engine can process the data. The learning from the analytics engine can be fed back to the machine which will help it become wiser and be prepared for a similar situation next time. This is Machine Learning, which basically means having specialized algorithms that help computers learn without actually having specific programming.

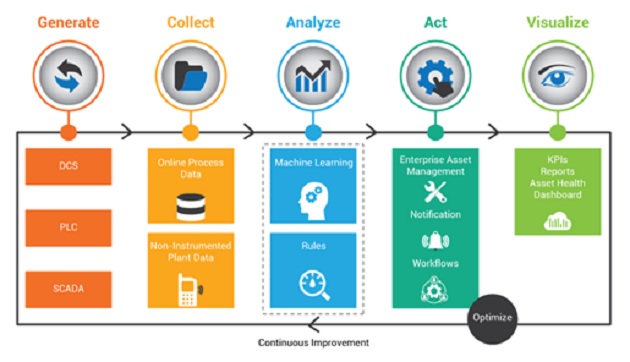

Machine Learning is key for realising Asset Performance Management, which is relevant for Industry 4.0. Here, the key input for Machine Learning is data from Asset.

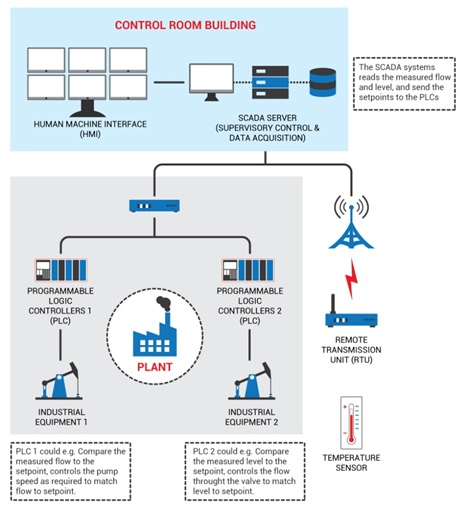

The assets could be old or new. There have to be mechanisms to bring data from asset either using existing communication infrastructure or by building new communication infrastructure (wiring) in the field. The analytics might use exiting sensors (which are part of control system) or need additional sensors to understand the performance (for applying ML) of asset (like vibration, temperature, etc.). There has to be proper integration of sensor data coming from PLC to supervisory and via some gateway/RTUs to supervisory systems.

The assets could be old or new. There have to be mechanisms to bring data from asset either using existing communication infrastructure or by building new communication infrastructure (wiring) in the field. The analytics might use exiting sensors (which are part of control system) or need additional sensors to understand the performance (for applying ML) of asset (like vibration, temperature, etc.). There has to be proper integration of sensor data coming from PLC to supervisory and via some gateway/RTUs to supervisory systems.

This requires some customization or integration of data and/or systems without impacting the process of the plant or factory floor. Companies like Sasken bring in partnership with different vendors and help to build complete solution by:

- Connecting new sensors to heavy machinery or equipment to collect data required for ML

- Collecting data from different legacy systems, supervisory, gateway and SCADA

- Sending data to cloud

- Machine learning and other enterprise system integration and

- Helping user to visually understand the performance of the asset

We can divide stages of IIoT enablement of your machines by:

- Identifying the correct parameter/data to capture

- Identifying and integrating appropriate sensors to collect the data

- Implement edge analytics/filter to sift out relevant data

- Implement an IoT gateway which can assimilate data from multiple machines/systems and then send it to cloud via appropriate long range connectivity technology

Once the data is there in the cloud you need to implement relevant cloud applications which make use of appropriate Machine Learning algorithm according to the use case/data characteristics. One way to divide Machine Learning algorithms, based on the category of problems that they can be used to solve or outcomes that they can help achieve, is as follows:

- Anomaly Detection

- Classification

- Clustering

- Regression

The details of each of these methods are given below.

- Anomaly Detection – Compare data over a window of time with similar preceding data. E.g. Flow meter data compared with similar flow meter data from immediate past will tell you if there is change in flow which might indicate a faulty valve or a leak.

- Classification – This generally is based on supervised learning where you train the algorithm based on past sample of failure data. Next the algorithm will make decision based on the current data and using previous learning. For e.g. based on vibration data of wind turbine gear box, one can classify whether the bearings are worn out or developing crack.

- Clustering – Group data based on patterns in the data-set. E.g. you want to classify vibration data into two groups bearing failure or lubrication failure. Here the algorithm will look at data set and try to find commonalities in the data parameters to group them into pre-defined failures. This kind of pattern detection can be used for detecting not only early signs of failure but also reasons of failure and can be leveraged to rectify the identified problem.

- Regression – These types of algorithms involve one or more independent variable and a dependent variable and based on values of independent variables we need to predict value of dependent variable. e.g. in case of Smart Buildings, based on weather patterns and room occupancy pattern you might want to predict an optimum room temperature. This is a classic use-case for Regression because here you are predicting a number which you might use to control the input and output of HVAC.

In summary:

The journey towards Machine Learning can be described as follows:

- Enable IIoT on your existing as well as new shop floor/plant/machines by

- Develop mechanism to collect data from machines and build connectivity mechanism

- Identify and develop appropriate algorithm for analytics

- Mechanism to loop back learning back to shop floor/plant /machines

By enabling IIoT in industrial solutions, companies like Sasken are transforming the raw data to actionable insights through Cloud Analytics. Under this umbrella, Sasken offers:

- Predictive Analytics based Maintenance: This solution leverages extensive machine learning based on historical data trends mapped onto present data trends or machine signature to predict probable future machine failure/ breakdown. The benefits include effective planning/scheduling of downtime based on machine prediction and more.

- Asset Track and Trace: This solution uses RFID based tracking tags to trace assets on real time. The analytics and machine learning techniques are used to predict the time to destination based on route optimization algorithms, speed of asset movement, weather conditions, etc.

- Augmented Reality based Field Support Operator services: Through this solution, Sasken empowers the technicians with visualization of faults which are invisible to naked eyes. The major benefits include reduced repair time, down time, cost etc.

As mentioned earlier, it is a combination of these four techniques that are used collaboratively to solve one kind of problem.

Contributed By:

Sasken Technologies Limited – (Ashish Mital, AVP – Digital Platform, Digital Transformation Services|Channabasavaraj Raravi, Senior Solutions Architect – Software, Product Engineering Services |Arunlal Sreedharan, Portfolio Manager – Industrials, Product Engineering Services | Debjyoti Ghosh, Assistant Manager – Industrials, Product Engineering Services)