When an organization is scaling manufacturing, there are many hurdles to overcome. It is a great thing to grow and expand, but you want to take appropriate steps and set yourself up for success. Scaling introduces more strain on the operation, who will need to add to their workload to meet new demands.

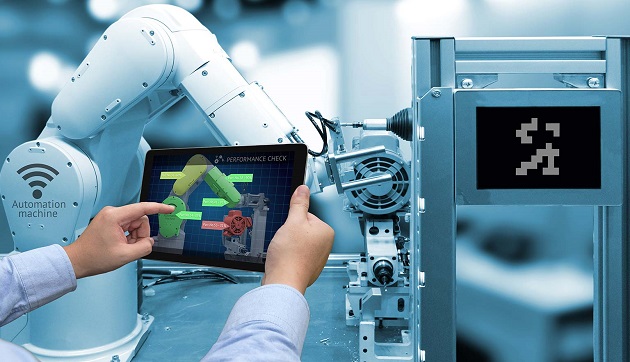

To be known as “cutting edge”, two things are needed: “skilled labour and the latest technology”. Fortunately, modern technology – Industry 4.0 or the Internet of Things (IoT) – can help you overcome these challenges and put you on the cutting edge of manufacturing.

Wireless Internet

One popular aspect of the Industrial Internet of Things is a wireless industrial network. This type of network allows a site to add and connect wireless devices quickly and efficiently. With an industrial wireless network, you can gain flexibility, security, and manageability – and save money while doing it. For an organization that is scaling its manufacturing, this could be a massive help.

As a general order of operations, first a wireless gateway is purchased and commissioned. Once in place, the wireless network becomes an enabler for the factory. With the initial hurdle dispensed, the factory can start adding wireless devices to its network and reaping the benefits.

An industrial wireless network allows an operation a great amount of flexibility. For example, if a device was not initially placed in the optimal position, it could be simply unmounted and moved to a new location. There are not wiring or conduit costs in this case.

From a security standpoint, an industrial network is safer than a business LAN. It is not connected to outside networks. Layers of protection are built between your machines and the outside, so that external influences cannot interact with them. Modern devices also utilize security strategies such as encryption and authentication, ensuring they keep your operation safe.

Manageability is another key benefit of an industrial wireless network. Commissioning devices is often very simple – turn them on and, connect them to the network. Software typically assists the user in making this process smooth and painless. It is typical to use a device management tool for help in this regard. When a business is growing, these types of tools are valuable to keep track of each asset.

Data Automation

Automating the flow of data can help tremendously when increasing production. If your operation is depending on people to complete many manual data entry tasks in their work, then scaling will require more manpower. But if you can start to automate these types of tasks, scaling the operation will be much easier.

Think of data automation as improving the flow of data through your factory. If the data is available in one system, it can be pushed to other legacy systems through automation. With automation you get an efficiency improvement, but also an error proof process. This can be accomplished in a number of ways, typically with a software package.

One technology that can help in this area is called Robotic Process Automation (RPA). RPA is a method to automate business processes. A business can design RPA to complete transactions, move and change data, and connect to other data systems. This type of technology can help add capacity for a growing factory. For example, a bank used RPA to add “more than 200 full time employees at approximately 30 percent of the cost.”

Maintenance

When you are growing, one area that you should examine is the maintenance department. If your maintenance cannot handle the increased load, the results could be disastrous. An ineffective maintenance strategy could reduce a plant’s capacity between 5 and 20 percent. With a manufacturing plant looking to scale, this is a problem. Additionally, the costs for unplanned downtime are estimated at $50 billion every year for manufacturers.

Thus, a proper maintenance strategy is critical to an operation that is growing. This means moving from a reactive based approach to a preventive and predictive methods. This shift in strategy is not always easy but it can yield substantial benefits – 10%-40% reduction in maintenance costs, 10-20% reduction in waste and 10-50% new improvement opportunities uncovered.

Predictive maintenance methods rely on machine conditions to guide the operation on when to service it. So rather than using preventive prescribed time intervals (or just waiting for things to break!), you can respond to real-time circumstances. This way allows you to predict when an asset will have problems and schedule corrective work before the disaster strikes.

Besides predictive maintenance, part of a proper maintenance strategy is in spare parts management. You want to have spares available for breakdowns, but not at the expense of tying up capital needed for expansion. A standardized work process using electronic inventory systems is needed, and software solutions that help you track and manage your inventory (e.g. send a notification when the stock level reach set thresholds) can be of great help in achieving this.

Conclusion

An expanding manufacturing operation is good for business, but not without its challenges to the production staff. Whether using industrial robots or something else to increase your automation, an IoT strategy has something to offer your growing operation. A wireless infrastructure is an enabler that helps your operation remain flexible, manageable and secure. Automation of manual tasks can lower the bar for your staff to take on the new workload. Of course, maintenance strategy should be considered and moved to predictive measures where possible. With modern technology these challenges can be overcome, setting your factory up to be on the cutting edge.

About the Author

Bryan Christiansen is the founder and CEO at Limble CMMS. Limble is a modern, easy to use mobile CMMS software that takes the stress and chaos out of maintenance by helping managers organize, automate, and streamline their maintenance operations.