Printed electronics advance toward wearables

That cool Apple iShirt and the matching Levi e-Jeans won’t go on sale for several years. But the field of printed electronics needed to produce them will make significant advances in 2017.

Fabric maker MAS Holdings and electronics manufacturer Flex, formerly Flextronics International, showed in July a safety garment embedding LEDs using materials they moved into production this year. The two companies are working to identify materials, connectors, encapsulation techniques, and antennas to fill in gaps between making electronics and fabrics.

At a printed electronics event last month, several makers of niche market medical and sports e-wear said that useful conductive yarns that can survive more than 100 wash cycles are now available. One expert said a year ago that an adequate supply of conductive yarns was emerging, though she complained about a lack of standards and benchmarks for them.

In May 2015, Google announced that it had a small team working on a project to use smart fabrics to create devices that could recognize gestures. Google started Project Jacquard in early 2014 with the goal of weaving touch and gesture interactivity into textiles using standard, industrial looms.

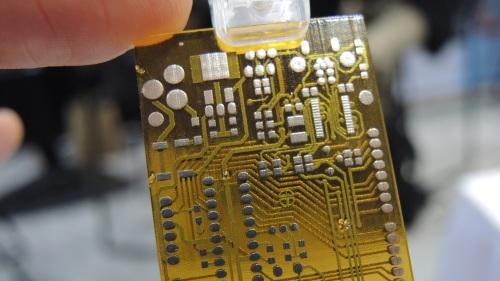

In addition to conductive fabrics, digital wearables need flexible components, batteries, and substrates to replace rigid printed circuit boards. Slow advances emerged on all of these fronts in the past year. For example, printed, flexible sensors were the talk of the annual Sensors Expo in June.

Startup Nano Dimension demonstrated an inkjet printer that uses conductive inks to print circuit boards, initially aimed at rapid prototyping. An executive noted in an article in April that such systems someday “will allow for circuits to be printed within objects, even playing structural roles if needed.”

STMicroelectronics is already making in a plant in Tours, France, printable, solid-state batteries that can be shaped. So far, their energy density is relatively low, but ST showed a roadmap leading to 20-mAh batteries.

The field of flexible, printed electronics is diverse and still embryonic, said Malcolm Thompson, executive director of NextFlex.

The NextFlex center was launched late last year with $165 million in funding over the next five years from a mix of sources, including the U.S. Department of Defense and a group of companies, universities, and other research centers. NextFlex will set up a pilot production facility in San Jose this year and help partners, including Flex, develop their own capabilities.

Printed, flexible electronics are “in a very formative stage” today, Thompson said. “There are some companies out there manufacturing these devices and processes, but … there is no large-scale flexible manufacturing anywhere in the world — but there will be.”

The center has already started a program with Ansys and Hewlett Packard Enterprise to develop EDA tools for printing with conductive inks transistors and other discrete components on plastic. “Today’s printed resistors, transistors, and diodes are not great, but … they are critical for reaching the sub-one-cent NFC tag — a Holy Grail in printed electronics,” said Jason Marsh, director of technology for NextFlex.

The U.S. is playing catch-up. Over the last decade, a handful of regional and national centers in Europe have invested several hundreds of millions in flexible, printed electronics.

China is playing catch-up, too. It is setting up its own research facility now with about $50 million in government funding for equipment, said Raghu Das, an analyst who follows the area at IDTechEx.

Beyond the core technology, the field needs a big systems integrator to act as a rain maker, said John Snow, a packaging specialist for Unilever that wants to put electronic tags on its consumer products.

“The big issue for us is integration; there are great ideas out there, but great ideas are only one piece of the puzzle — we need to put together all of the pieces to bring the technology to life, so we need a collaborative group,” said Snow.