In the changing scene of industrial automation and electrification, another part of the PDS systems has found its way into the power drive system of the electrical motors in a large number of applications-ranging from robotics to conveyors, to HVAC systems and various industrial pumps. At the center of power is the semiconductor that determines the efficiency, performance, size and cost of the drive systems.

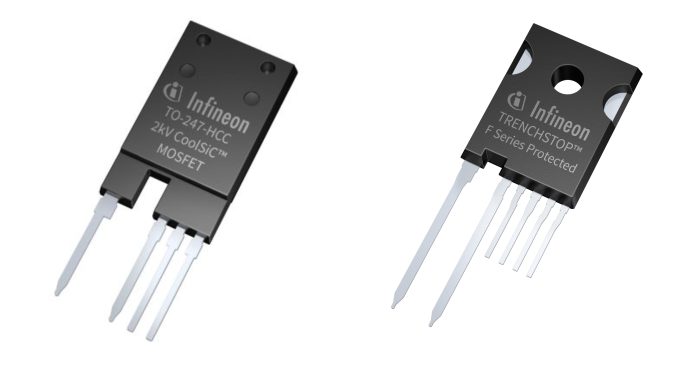

Two of Infineon’s most widely admitted semiconductor technologies used in this space are:

CoolSiC, a wide bandgap Silicon Carbide (SiC) MOSFET-based technology and TRENCHSTOP IGBT, a mature and cost-effective IGBT technology.

While both serve the same purpose of converting and controlling electrical power, each comes with its strengths and limitations. This article presents a detailed and data-based comparative analysis of these two technologies for real world PDS applications, touching upon efficiency, efficiency, switching performance, thermal characteristics and total system cost.

Technology Overview

CoolSiC (SiC MOSFETs)-

CoolSiC MOSFET capitalize on the physical features of silicon carbide, the wide-bandgap material being known for its high thermal conductivity, high breakdown voltage, and low switching losses.

TRENCHSTOP IGBT-

In the TRENCHSTOP IGBT, trench and field-stop technologies coalesce to enable low conduction losses and fast switching at a reasonable price. In traditional motor drives, this time-tested silicon-based technology still capitalizes on robust operation and hence enjoys very good price-performance in the general-purpose drives.

Benchmark Setup: Simulations and Measurements

To evaluate the performance of the two technologies, Infineon had simulated and experimentally tested them on a typical PDS architecture:

Application: 3-phase, 400 V AC, 7.5 KW motor drive

Topology: 3-level inverter

Modulation Strategy: Sinusoidal PWM

Switching Frequency:

IGBT – 8KHz

CoolSic – 40 KHz

Cooling system: Passive heatsink, same ambient conditions

Load Profile: Constant speed, variable torque

Efficiency Comparison

Energy efficiency of the drives is a pressing concern, directly impacting energy bills and CO₂ emissions.

| Technology | Peak Efficiency | Average Efficiency (Load range: 30-100%) |

| CoolSiC | 98.5% | 97.8% |

| TRENCHSTOP IGBT | 96.8% | 95.1% |

Peak efficiency of the CoolSiC inverter is around 2 percent higher than that of the TRENCHSTOP solution. The higher switching frequency made for better waveform quality with lower harmonics, thus causing motor heating and system losses.

That means too much saving on energy by about 8 to 12% during the lifetime of a drive, specifically in high-duty applications such as HVAC, pumps and compressors.

Switching Performance and Losses

Being a unipolar device equipped with fast-switching features, CoolSiC turns out to be batter than an IGBT in turn on as well as turn off switching losses.

| Parameter | CoolSiC | TRENCHSTOP IGBT |

| Turn-on loss | ~0.3 mJ | ~2.5 mJ |

| Turn-off loss | ~0.2 mJ | ~2.0 mJ

|

| Total switching loss per cycle | ~0.5 mJ | ~4.5 mJ

|

The losses incurred by IGBT goes by the hour at high switching frequencies (exceeding 20 kHz); meanwhile, CoolSiC has linear loss scaling, giving it an edge in precision motor control applications.

Thermal Behavior and Heatsink Requirements

With less power loss, less is generated in thermal energy. This reduces the heat dissipation of the system, thus affecting the cooling requirement and the size of the system.

| Metric | CoolSiC | TRENCHSTOP IGBT |

| Junction temperature | ~80°C | ~105°C |

| Required heatsink size | 30% smaller | Baseline |

| Cooling system complexity | Simple/passive | More advanced |

The size of the CoolSiC modules is significantly less. Also, this possibility opens the opportunity for fan-less or sealed enclosures, which is perhaps important in a dusty environment.

Impact on Motor Performance

The possibility of CoolSiC switching at higher frequencies brings about better sinusoidal output waveforms benefitting motor performance.

| Motor Performance Aspect | CoolSiC | TRENCHSTOP IGBT |

| Acoustic noise | Lower | Higher |

| Torque ripple | Reduced | Noticeable |

| Motor temperature | Rise 8-10°C lower | Baseline |

Using CoolSiC inverters will certainly increase motor efficiency and longevity, especially in applications involving servo drives or high-speed ones where fast transient response and high precision are required.

System-Level Cost Analysis

Through the true cost of a CoolSiC device is mostly on per unit basis, the story of the system cost is usually quite different.

| Cost Element | CoolSiC | TRENCHSTOP |

| Semiconductor cost | Higher | Lower |

| Cooling system cost | Lower | Higher |

| System size and weight | Smaller | Larger |

| Total Cost of Ownership (TCO, 5 year) | ~10–15% lower | Baseline

|

Indeed, CoolSiC’s greater energy efficiency in long duty cycles brings down operating costs and ensures a speedy ROI and better sustainability profile.

When to Use Which Technology?

| Application Type | Recommended Technology | Justification |

| High-speed servo drives | CoolSiC | High frequency precision, low noise |

| HVAC systems | CoolSiC | Energy efficiency, compact size |

| Pumps and Compressors | CoolSiC | Lower energy consumption over time |

| Budget-sensitive drives | TRENCHSTOP IGBT | Cost-effective for <15KW systems |

| Harsh industrial environments | CoolSIC | High thermal tolerance, robust design |

Conclusion:

There is no doubt that CoolSiC technology from Infineon sets the benchmark for the next generation of industrial drives in terms of efficiency, compactness and performance. In a high-performance, space-restricted or energy sensitive environment, SiC can make designs which are small, cool, sustainable and future-proof.

However, to TRENCHSTOP IGBT remains the preferred option where cost considerations dominate and the switching-frequency and thermal load requirements on the system are moderate.

With the trend of industrial systems towards smarter, greener and digitalized infrastructures, the usage of wide bandgap semiconductors such as CoolSiC can farther be expected to grow exponentially.