Here is the list of connector companies that most stand out in this ever-changing industry. It’s no easy task to keep up with the next big innovation — especially when that phenomenon is occurring across multiple markets. The ELE Times top five companies are among the gems and very useful to the user community in identifying, researching, and selecting the companies with whom to partner. The quest for the right supplier for your company is not easy. However, identifying the companies under various definitions makes a difficult task easier.

HARTING India:

Every crisis offers an opportunity, Dr. Girish Rao, CEO, HARTING

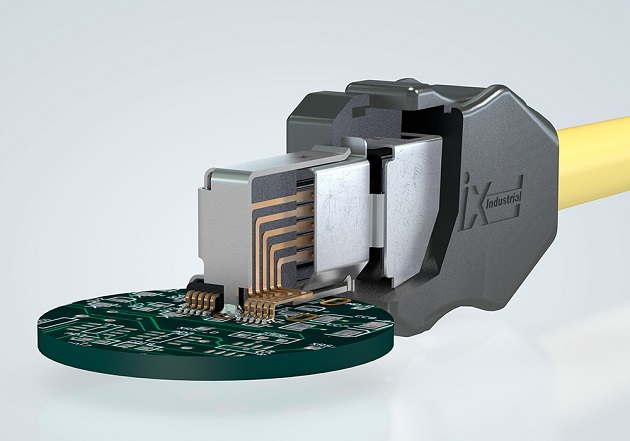

HARTING is a global leader supplying connectivity solutions for the three main lifelines of industrial technology – data, signals and power – with 14 production sites and 43 sales companies worldwide. HARTING India seeks to enhance the country’s Industrial capability and competitiveness to become a Global Player in terms of Technology and Markets by providing the latest technology and innovative Interconnection solutions.

Products: Industrial connectors Han, MICA, Industrial Ethernet switches, RFID, PCB Connectors, Interface Connectors, System Cabling.

New Technology: HARTING also launched 5 new products and 6 updated products and upgrades for electronics segment amidst COVID 19 from March to September.

New Products: DIN power Type G, InduCom 9 PCB board connector, Single Pair Ethernet – HARTING T1 Industrial connect, cable and assemblies, M8 and M12 D-, P-coding connectors and har-Drive – new signal and power interface.

Market: When it comes to connecters, India is expected to grow one of the top three markets by 2025 globally in absolute size. The growing ecosystem in manufacturing, transportation and infrastructure combined with green technology, automation and other trending concepts are influencing factors in the growth of the Electrical and Electronics sector. This is a positive sign to connector manufacturers to focus on various needs in Electrical and Electronics.

HARTING provides connectivity solutions to power, signal and data catering to wide spectrum of applications to various industries. Our connectors are majorly supplied to transportation, wind, machinery and power generation and distribution with a leading 30% of the total market share. With the increasing demand for industrial electronics, HARTING connectors’ share have significantly risen to 40%.

Current Demand: Miniaturization in connectors is the major force to drive market needs. Connectors delivering more power, data and signal options with smaller sizes are likely to rule. High capacity hybrid connectors that can provide easy configurable solutions, ready availability and good design to satisfy a wide range of power, signal and data connection requirements with compact sizes will also play a huge role. High capacity single pair ethernet connecters, which are niche and highly demanding in the market are promoted by few players like HARTING. More power and more bandwidth are some of the current trends that are likely to drive the electronics market.

R&D: HARTING continues to focus on Transportation, Power, Machinery and Robotics, Automobiles, Wind and Industrial electronics sectors. The company is planning to expand the product offerings to upcoming sectors such as data center, energy storage systems and e-mobility. Currently on low demand – low volume, these sectors are poised to grow globally with rapid changes in policy regulations. It is anticipated to be high potential sectors with future demands and early-bird advantages.

The focus on R&D is the key to HARTING’s plans to expand connectors market in India. More localized products, application and industry-wise customized solutions will be conceptualized, designed and manufactured in India to compete and gain small and medium manufacturers. In the forthcoming years, HARTING hopes the electrical and electronics industries work hand in hand with connector manufacturers at the design level for structural and performance advancements.

HARTING about ‘Make in India’: Indian electronics sector is becoming more and more diverse. The whole sector is going through a radical change. This transition phase is the growth driver for connector manufacturers. The range of customization in products is increasing rapidly, so the industry is largely dependent on global player to fulfil the growing needs. With the current government’s “make in India” initiatives, HARTING is already contributing to the nation in different ways. The company see Indian market becoming very aggressive and open to new products and solutions. They also see a great opportunity to expand product portfolio, develop more localized and customized products and manufacturing capacity.

HARTING about the challenges faced during the COVID 19: HARTING too had a very difficult time to sustain the business continuity during COVID phase mainly because of lockdown. With more and more projects on hold from customer end, it was a standstill moment to a few target sectors, Supply chain was a major issue, bottle necks in importing materials and increased cargo cost were huge challenges. But sectors like railways and power continued to do well for HARTING. Digital initiatives played a vital role during this crucial phase in new business development, order bookings, new product launches, training and other services.

Dr. Girish Rao, CEO, HARTING

OMRON India:

A global leader in advanced Sensing, Control + Think technologies spanning across advanced industrial automation, electronic and mechanical components and home healthcare, commenced operations in India in 1980.

Today, through its rich and unique portfolio, OMRON endeavours to contribute towards making India progressive by bringing innovation and values to innumerable fields of manufacturing sector, IIoT, Robotics, Artificial Intelligence, Automotive, Energy, Industrial, Infrastructure, Medical Equipment, Home Healthcare monitoring, to name just a few.

Products: Relays, Switches, Connectors, Sensors and Protective devices and more.

Market: It caters to automotive, power, telecommunications, etc.

New Technology:

- DcX (Decentralized X: Aggregating Heterogeneous and Decentralized AIs)

- FORPEHUS is State-of-the-art technology that embodies the world of “harmony” where machines can bring out human ability.

- Visual inspection systems (AOI)

- Integrated IoT sensor

Manoj Manoj Kodakkatery, Manager-Business Development, OMRON Electronics and Mechanical Components business division, India

“OMRON strives to deliver the best value to the customers by focusing on key deliverables like improving the workability during production, maintenance and reliability for manufacturers belonging to Factory Automation and Automated Test Equipment industries. This gets translated into varied product feature-based value additions like production time saving, strong locking mechanisms, easy insertion and extraction, etc. Also, being a leading sensing and control technology provider, we are using advanced technologies like EFC (Electro Formed Components) technology to realize a long-life span for connector components which is one of the major requirements & needs of the industry,” says Manoj Manoj Kodakkatery.

WAGO:

Wago is a 25 years old company mainly dealing in Electrical Technologies. It offers an unrivalled range of advanced Electrical Interconnection and Automation products. WAGO manufactures terminal blocks connectors along with multi connection systems, connectors and related accessories. WAGO’s USP is spring technology rather than the usual screws.

Products: Rail mounted terminal blocks, Connectors, PCB terminal blocks, Components for automation, etc.

New Technology:

- Portfolio Expansion of the TOPJOB S Rail-Mount Terminal Block with Lever

- WAGO topjob S Mini Terminal Blocks with a Compact design

- New Pluggable 252 Series PCB Terminal Block WAGO MCS

- WAGO Gelbox

- WAGO’s junction box – 221 Series

- WAGO’s 221 Series Adjacent Jumper

- WAGO’s X-COM-system

- New slimline n-conductor and power distribution disconnect terminal blocks

- Hands-free mains connection

- Double-deck terminal blocks with push-buttons and vertical conductor entries

- Tool-free conductor termination for 10 MM2 (8 AWG) conductors

Market: It caters to Automation, industrial and electronics Industry. WAGO products are used globally in power and process technology, building automation, machinery and equipment, as well as industrial and transportation applications.

Current Demand: Large demands have arisen for infrastructure, networks, controllers, and flexibilities, which were previously provided by controllable power plants. Biomass as the single, controllable renewable energy appears to be limited; instead, solar and wind energy have dominated the field. The problem is that electrical production in the decentralized systems fluctuates with the weather. Therefore, in addition to new networks, technologies that provide flexibility, like batteries, are necessary both to store excess current and supply it as needed. In addition, the demand for electricity must become more flexible. Up until now, supply has followed demand. This becomes more difficult at increasing levels of fluctuating supplies.

R&D: WAGO products are designed for complex application requirements. WAGO is well-known in the market for quality range of terminal blocks and core spring pressure connection technology. Last few years have shown an encouraging acceptance of company’s interface and automation control products by its customers.

Upcoming WAGO production facility in Vadodara is expected to be operational as early as next year. This will enable WAGO to cater to growing demand for products in large set of industries in India. In the phase one, Wago expects an investment of Rs 250 crore.

WAGO on ‘Make in India’: WAGO follows same standards of production across global manufacturing units to maintain standardisation of quality irrespective of location of production. Certain products are earmarked to a certain factory. The products manufactured in India will go to all location whether in China, Germany or any other country. This enables Wago to achieve high standards of quality.

WAGO about the challenges faced during the COVID 19: Overall the business was similar as last year. While we did not significantly increase our revenue, we did see certain improvement in key strategic segments which is very encouraging for us. We also saw an increase in our exports by 4 per cent. We are nicely placed with our strategies that we planned for further investments in India, says Alok Kishore, CEO, WAGO India.

Alok Kishore, CEO, WAGO India

“We are grateful to our customers, partners and enablers for their trust in us to deliver quality products and services. Their demands, challenges and feedback have pushed us to continuously upgrade and improve ourselves. Our success story remains incomplete without thanking relentless efforts of WAGO India employees ensuring the positive customer experience at every step. We rejoice in our hearts on a job well done and keep the spirits alive for the future,” says Alok Kishore.

TE Connectivity

A technology company that designs and manufactures connectivity and sensor products for harsh environments for a variety of industries, such as automotive, industrial equipment, data communication systems, aerospace and defence, medical, oil and gas, consumer electronics and energy.

TE Connectivity has a global workforce of 80,000 employees, including more than 8,000 engineers. The company serves customers in approximately 140 countries. With employees, customers, engineering centres and factories around the world, and sales coming almost equally from the Americas, Asia/Pacific and EMEA regions, TE have the advantage of being a truly global industrial technology leader.

Product: Antennas, Application Tooling, Cable Assemblies, Connectors, EMI Filters, Fiber Optics, Harnessing, Heat Shrink Tubing, Identification & Labeling, Passive Components, Power Systems, Relays, Contactors & Switches, Sensors, Terminals & Splices, and Wire & Cable.

New Technology:

- 0mm Locking Wire-to-Board Connectors

- MS5839 Chlorine Resistant Digital Pressure and Temperature Sensor

- 5mm Sealed Signal Double Lock Connectors

- Locking Flexible Printed Circuit (FPC) Connectors

- SOLARLOK 2.0 Connector

- TE Antennas for Wi-Fi 6E

- TE Antennas for 5G, NB-IoT and LTE-M

- RZF Power Relays

- M3200 Compact Industrial Pressure Transducer

- Economy Power 2.5 Connectors

- Dynamic Series D-2970 Flex Push

- BATTU Dual Wall Heat Shrink Tubing

- STRADA Whisper R Backplane Connectors

- MULTI-BEAM Plus Power Connectors

- High Power Pin & Socket Connectors

Market: It caters to power electric vehicles, aircraft, digital factories, and smart homes. Innovation that enables life-saving medical care, sustainable communities, efficient utility networks, and the global communications infrastructure.

Current Market Demand: Products with robust design and high-power capacity are commonly needed for high-speed data communication applications, such as servers, switches and storage. These applications’ board-to-board and board-to-busbar connection normally cannot be fully realized through other solutions like cable assemblies due to limited space and high-power density request.

TE is accelerating pace along with market trends, introducing new reliable antennas to the market, offering customers quick-to-market solutions while delivering optimal performance to create a safer and connected future even in the face of harsh environments.

The growth of cellular IoT devices drives market demand of products for 5G and cellular low-power wide-area network.

R&D: TE’s innovative design and strong technical support empower high-power pin and socket products’ reliable performance for high-speed data transmission among high-power applications.

The digital era is here for industrial manufacturing. TE is innovating a flexible solution for older equipment allowing these machines to connect to a network, enabling them to communicate with each other and with operators in real time.

TE connectivity on ‘Make in India’: TE Connectivity, a $14-billion manufacturer of connectors for electric, electronic and internet systems, has already established an integrated manufacturing facility in Bangalore at an investment of ₹300 crore.

The plant, one of the first in the Aerospace Park supports the growing local market and exports. The plant, measuring 280,000 sq feet, has created jobs in areas of assembly, packaging, molding, stamping, tooling machine components, cable processes, etc.

At present, the technology-focussed TE Connectivity has nearly 300 design engineers (80 per cent in Bangalore) in India, addressing various sectors such as automotive, defence and aerospace, renewable energy, telecom and railways. The company with seven manufacturing plants—five in Bangalore and two in Pune—employs up to 4,000 people and has a turnover of nearly ₹1,500 crore in India. It also has two joint ventures – one with the RPG Group for power and energy products, and the other with Kochi-based CII Guardian to make relays for defence and allied applications.

The MNC, which has been present in India for around 25 years now, designs and manufactures more than 700000 products such as electronic connectors, components and systems that connect and protect the flow of power and data inside myriad products that touch every aspect of our life.

The Switzerland-based company, is betting big on four broad areas to spur growth in automotive and telecom; renewable energy and defence and aerospace.

TE connectivity: About the challenges faced during COVID 19: The current COVID-19 crisis has reinforced market conviction that EVs are the future of Automaking. While the media talk focuses on new architectures and powertrains, from a connectivity standpoint, TE focuses on safety and reliability. Connectors are playing an ever more important role as automotive systems get ever more integrated. The industry is dealing with increased challenges such as thermal management, noise management, vibrations, and redundancy. OEMs will look to expert partners like TE to provide them solutions that perform to their exacting design requirements.

Terrence Curtin, CEO, TE connectivity

“At TE, we have had an ongoing and transparent record of environmental, social and governance reporting through our annual corporate responsibility report and I’m proud of our progress over the past 10 years. Now, we are evolving our strategy to the next level with One Connected World, which builds on our purpose of creating a safer, sustainable, productive and connected future and provides a roadmap for us to make a measurable impact over the next decade,” says Terrence.

Phoenix Contact

Phoenix Contact is one of the leading technology company since its inception in 1993. With innovative products in the range of Terminal Blocks, Connectors, Interfacing Solutions, Surge Protection Devices and Automation Components, Phoenix Contact India has offered value added solutions to the different industrial segments including Energy, Process, Machine Tools, EMS, Railways and Telecom etc.

Products: Cables and lines , Charging technology for e-mobility, Cloud computing, Connectors, Electronic switching devices and motor control, Electronics housings, Functional safety, HMIs and industrial PCs, Industrial communication technology, Installation and mounting material, Lighting and signalling, Marking and labelling, Measurement and control technology, Monitoring, PCB terminal blocks and PCB connectors, PLCs and I/O systems, Power supplies and UPS, Protective devices, Relay modules, Sensor/actuator cabling, Surge protection and interference filters, System cabling for controllers, Terminal blocks and Tools.

Market: It caters to Communications, energy and power, aerospace, defence and marine, and much more.

New Technology:

- M17-M40 PRO series circular connectors

- M12 H and Y distributors for power transmission

- M23 hybrid device connectors

- PRC series angled circular connectors

- Double-row PCB connectors

- Feed-through connectors with 5.08 mm pitch

- DC distributors for photovoltaic systems

Roland Bent, CTO, Phoenix Contact-Group

“With our future-oriented innovations, we are paving the road to the networked world for you. Be inspired by new products that create real added value in your application,” says Roland Bent.