Danish Technological Institute (DTI) is leading a new European innovation hub, intended to help the manufacturing industry achieve a strong global position and prepare for Industry 4.0. The key is printed electronics – a technology that makes it possible to print conductive circuits on just about any surface.

What do a contactless payment card, an ECG electrode and an industrial IoT component have in common? They all contain small electronic components that makes it possible to perform wireless readings or activities – in the above examples: payment, measuring heart beat frequency and monitoring environmental parameters such as humidity or temperature.

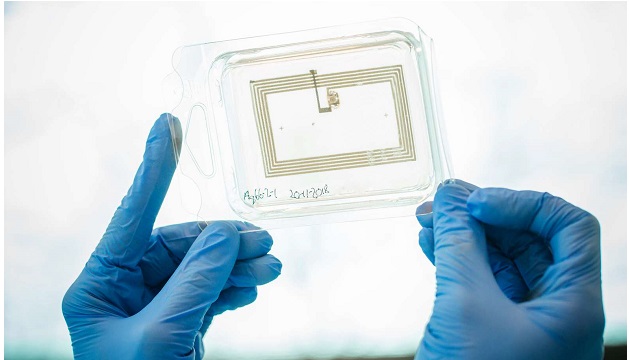

The conductive components in intelligent products are embedded to an ever-increasing degree using specialized industrial printers, employing ink jet and aerosol jet technology to print a very fine layer on supple materials such as plastic sheet, paper and textiles. The technology is called ‘printed electronics’.

Similar to 3D print

“Printed electronics opens up a whole world of new opportunities, as complex constructions can be embedded just like using 3D printing, at prices able to compete with mass-produced goods. Quite simply because electronics can be produced from CAD drawings and printed on flexible materials, as already used in architecture and 3D print,” explains DTI’s Project Coordinator, Zachary James Davis.

€ 10.6 million earmarked for printed electronics

Researchers at DTI have been working with the technology since 2016. Teaming up with 16 RTOs and leading businesses across Europe, DTI has just been awarded, through Horizon 2020, € 10.6 million to develop an open innovation test bed (LEE-BED). The test bed – which functions as an innovation hub – focuses exclusively on printed electronics, the market for which is already estimated at a value of USD 32 billion outside Europe alone.

Europe needs to catch up

Europeans have not been as quick as the rest of the world to appreciate the benefits of the new technology. LEE-BED intends to support implementation of printed electronics in Europe.

“All the partners in LEE BED will provide their various skills and facilities within printed electronics to enterprises that want to integrate and embed electronics into their products,” says Zachary J. Davis.

Access to expensive facilities without financial risk

Enterprises can apply to join LEE BED, whereupon their business case will be evaluated. If deemed to be suitable for participation in LEE BED, they will get access to those RTOs that best match their requirements. They will also have access to equipment and expertise from designated RTOs to support development efforts from prototype through pilot production to full-scale manufacturing.

“Enterprises will be able to prove the viability of new technologies without major investment and financial risk during the all-important initial phase. We have already started working with jewellery giant Swarovski, looking into the idea of intelligent light in their crystals that can be integrated with clothing and home interiors,” concludes Zachary J. Davis.

For more information, visit: lee-bed.com