The drive to reduce the use of fossil fuels is accelerating. Vehicle electrification is becoming increasingly important for countries aiming to meet net-zero targets. As coal and other fossil fuels are phased out, petrol and diesel vehicles account for a larger proportion of fossil fuel usage.

With electric vehicles (EVs) comes the inevitable question of charging. Overnight charging on a slower-speed charger is acceptable for a lot of personal and light goods vehicle (LGV) users. However, if electric vehicles are to fully replace those based on the internal combustion engine (ICE), there are numerous situations where much faster charging speeds are needed.

For example, battery-powered buses and trains need to be capable of taking on sufficient charge during what are often relatively short times at stops or stations. Elsewhere, electric heavy goods vehicles (HGVs) will need to have a means of quickly charging very large batteries without significantly impacting operators’ working patterns.

To achieve the necessary charging speeds, high-voltage rapid and ultra-rapid DC chargers are essential, capable of delivering power at up to 500 or 600 kW and thereby enabling recharge times of under 10 minutes (depending on the battery size).

Forecasters expect an enormous investment in this technology over the coming years. A recent report by Deloitte, for example, estimated that in the UK alone, there will be more than 120,000 rapid and ultra-rapid EV charge points by 2030 and that the overall annual spend on EV charging infrastructure could hit £3 billion ($3.7 billion, €3.5 billion) by this date.

However, for the organizations and engineers responsible for designing these DC EV charge points, pushing voltages upward leads to a variety of challenges.

This article explores some of the primary ones and touches on what design teams can do to address them.

A typical DC EV charging system

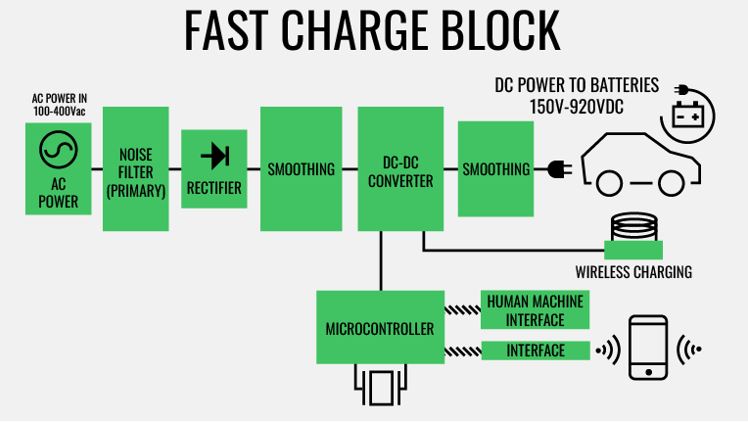

This high-level overview of a DC EV charger shows the stages involved, from converting an AC source to a high DC voltage

This high-level overview of a DC EV charger shows the stages involved, from converting an AC source to a high DC voltage

A DC EV charger will typically take a mains AC feed of between 100 and 400 V and after some noise filtering, pass the current through a full-wave rectifier and a smoothing filter to drive a DC-DC converter. The DC-DC stage steps the low-line voltage from the AC supply up, to the high-line voltage the vehicle requires. The DC-DC conversion block comprises a low power DC-DC converter that drives silicon carbide (SiC) or IGBT high-power switching devices. Engineers must trade-off maximizing system efficiency — through fast switching — against minimizing EMI or noise by using lower switching frequencies.

Having outlined the basics of DC EV chargers, let’s look at six areas to consider when choosing components and designing your charging system, particularly for the low-power DC-DC converter.

- Ensure your components are suitable for the environment(s) in which they’ll be used.

EV charging infrastructure typically has long expected lifespans – up to 20 years in some cases. It can also be exposed to extremely harsh and changing conditions, from glaring sun during the day to frosts at night. It may also be subjected to variations in humidity as well as a variety of physical pressures, such as shocks and vibrations. Moreover, the high output currents can lead to very high temperatures, potentially requiring cabling to be water-cooled if it is openly accessible.

When selecting components, make sure you pick those that have been tested and guaranteed to withstand the rigors they’ll face in your application. A key factor is a component’s ability to cope with repeated temperature cycling, so look for those that are subjected to intensive tests in this respect, particularly for gate-drive applications.

- Ensure that your SiC/IGBT gate drive voltage goes negative to turn it off.

While a SiC or IGBT device’s datasheet will typically show 0 V as the turnoff voltage, this is often at ambient temperature rather than across its full operating range. In practice, threshold voltages can vary across temperatures; a SiC device can potentially have a threshold voltage of 1.5 V at high temperatures.

By driving the off voltage to 0 V, the voltage can drop through the gate threshold relatively slowly, which leads to slower switching (although it will minimize EMI). However, if the threshold varies, then so will the switching point. Conversely, if the target off voltage is negative, the voltage will drop through the gate threshold more quickly, with less variation in the switching point. This gives you much higher certainty your device will be off when it should be.

Moreover, there’s less risk of excessive power dissipation during a switching edge and less risk, once the device is off, of shoot-through caused by things such as the Miller capacitance effect, turning the device back on. Lastly, a negative gate voltage also protects against the lead inductance effect.

- Choose a DC-DC converter rated for high continuous voltage.

When selecting your DC-DC converter, you need a product rated for high continuous voltage. This is sometimes called DC link voltage, or non-safety continuous working voltage. You may also require a high level of safety insulation. Many general-purpose DC-DC converters may claim test voltages as high as 3 kV. However, they may only have been tested to withstand this for very short periods – as little as a second in some cases. If this is the case, the chance of the product quickly failing if used in a rapid or ultra-rapid EV charging application is high.

You should also pay attention to the insulation class. Without information about this, the safety-approved voltage is of little value because it won’t tell you whether basic/supplementary or reinforced insulation will be required for your application.

- Pick a DC-DC converter with sufficient partial discharge immunity.

Partial discharge immunity is incredibly important in DC EV charging systems due to the high switching voltages the components will be exposed to. Gate drivers are typically specified with a partial discharge value. But the DC-DC converter will be under the same insulation stress, and the most common cause of electrical failure in applications such as this, where the insulation is constantly under stress, is the breakdown of the isolation barrier.

You’ll usually find the best partial discharge immunity in products with physical spacing between the transformer primary and secondary, and a single solid barrier with tight control of voiding. Consequently, products with wire-on-wire transformers, which tend to have no physical spacing and don’t have tight control of voiding, aren’t recommended for this type of use case.

A related point to note is that as well as the high switch voltage across the DC-DC converter, the waveform’s edge speed (dV/dt, which can be as high as 200 kV/µs) can also stress its insulation.

- Look for very low isolation capacitance in your DC-DC converter.

Your DC-DC converter needs to have as low capacitance as possible – ideally less than 5 pF. This is because when you’re switching at high voltages, capacitance within the transformer generates a current. For example, even if you have a seemingly low capacitance of 10 pF and a very low switching rate of 30 kV/µs, you could still generate 300 mA of current. If this finds a return path through the system earthing to the switch, you can get voltage drops across resistances and inductances. These voltages create EMI, which might result in interference or damage to the device.

Another reason why isolation capacitance is so important is that, with the higher switching frequencies in SiC and gallium nitride (GaN) devices, you may start to see the clipping of the waveforms.

If you can’t get a DC-DC with a sub-5 pF capacitance or you’re seeing a current level that’s still too high, then add a common mode choke in the input of your DC-DC.

- Mind these physical considerations.

Lastly, it’s important to think about the physical design of your system and to consider power from the start of the process. In this type of application, you want your DC-DC converter as close to the gate driver as possible. This, in turn, needs to be as close to the IGBT/SiC device as it can be so that you minimize signal noise. It may be possible to put the DC-DC underneath or alongside the gate driver. In any case, with many engineers finding that height is a problem, it can be helpful to look for low-profile solutions.

Taking your next steps

Many local, national and regional governments have put vehicle electrification at the core of their strategies to tackle climate change. Many set ambitious targets for the removal of new ICE-based vehicles from sale – some as early as 2025. This shift to electric, particularly in larger and higher-usage vehicles such as HGVs, buses and trains, brings with it the need for significantly faster charging capabilities. This will reduce EV charge times to something that approaches refueling an ICE vehicle.

For the engineers designing the high-voltage DC chargers that will enable this, significant challenges must be overcome. As a result, careful consideration needs to be given to system design and component choice.

Courtesy: Murata