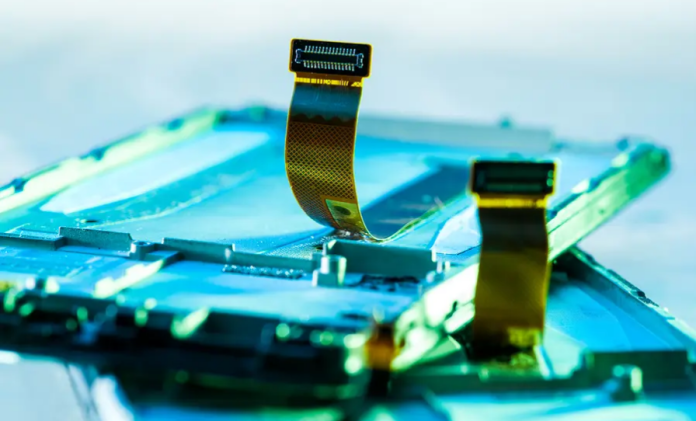

When developing specialty interconnects such as flexible circuits, rigid-flex circuits, flexible heaters, or membrane switches, the primary goal is to ensure these components can perform reliably in challenging applications. Trends like miniaturization, connectivity, wearables, and mobility necessitate the use of specialty interconnects over traditional rigid PCBs. The design phase is crucial to achieving a high-performing specialty interconnect.

The Importance of Design Expertise

Design expertise is pivotal in creating an effective specialty interconnect. Customers often seek custom solutions tailored to their specific applications, and the design phase involves several key considerations:

- Material Selection and Properties: Understanding the materials and their properties is essential for creating a reliable interconnect.

- Mechanical and Electrical Challenges: Determining how the circuit will be used and addressing any mechanical or electrical challenges that may arise.

- Environmental Conditions: Considering the environmental conditions the circuit will face.

- Installation and Usage: Ensuring the design accommodates the installation and usage requirements of the circuit.

Benefits of Working with Experienced Application Engineers

Experienced application engineers bring significant value to the design and development process:

- Cost-Effective Solutions: They can identify cost-saving opportunities, such as reducing the number of layers or optimizing design features.

- High Yields: Expertise in pushing and relaxing design rules to achieve high yields.

- Faster Development: Their experience allows them to resolve issues quickly and efficiently, reducing the number of design revisions needed.

- Prototyping and Troubleshooting: Expert engineers can quickly identify and address problems during prototyping, saving valuable time and resources.

- Design for Manufacturability: They ensure the design can be manufactured reliably and cost-effectively.

Case Studies

Rapid Issue Identification: A top flex engineer quickly identified a problem that in-house engineers had been unable to resolve for weeks, highlighting the value of expertise.

Costly Mistake with Low-Cost Supplier: A customer initially chose a low-cost supplier without design expertise, leading to significant delays and increased costs due to multiple revisions and performance issues. Switching to a supplier with design expertise ultimately resolved their issues.

Conclusion

To build a better specialty interconnect, start with the design phase and partner with experienced application engineers. These experts will guide you to cost-effective, reliable solutions and help you avoid costly pitfalls. By choosing a supplier that combines superior expertise with competitive pricing, you can achieve the greatest overall value and develop a better specialty interconnect.