Taking x-ray images goes back over 100 years. Since then, there have been numerous advances in terms of x-ray tube and x-ray detector technology and these have been increasingly applied into helping with the manufacturing of electronic components and assemblies, as well as in their failure analysis.

Most recently, this has been rapidly driven by the continued reduction in board, device and feature size and the movement to using newer, lower density materials within the structures, such as copper wire replacing gold wire as the interconnection material of choice within components. In order to meet these challenges and those in the future, there have been a number of recent key improvements to the vital components within x-ray systems. In particular, there is a new x-ray tube type that permits high magnification inspection at improved resolution, yet retains high tube power under these conditions, allowing good x-ray flux for inspection of the smallest features.

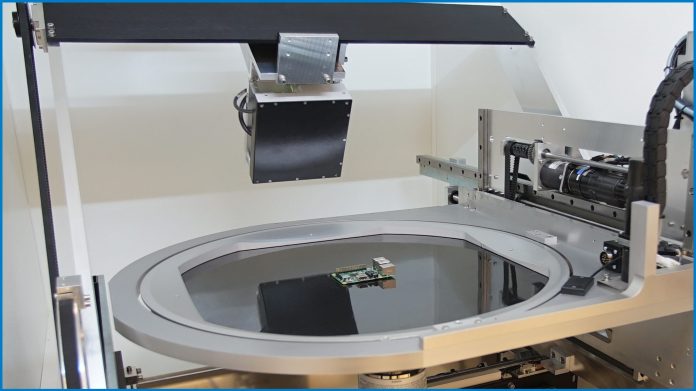

There is also the availability of new and improved x-ray detectors (both image intensifiers and Digital Flat Panels) that are now specifically designed for electronics applications, rather than hand-me-downs from the needs of the medical market, which are able to take best advantage of these tube developments.

The choice of available technologies, however, means selecting the tube/detector combination, which is optimum for a particular electronics inspection application, is no longer so clear-cut. For example, one configuration may provide certain benefits that are applicable for one area of electronics inspection, whilst being less valid for others. This paper will review the various x-ray tube and detector types that are available and explain the implications of these choices for electronics inspection in terms of what they provide for inspection regarding image resolution, magnification, tube power, detector pixel size and the effects of detector radiation damage, amongst others.

It will also suggest optimum configurations for the main electronics inspection tasks required today. The increasing use of copper bond wires to replace the gold wire used for many years is one example where the type of flat panel technology can have a significant effect on the resultant images.