The Rise of Electric Vehicles

The worldwide electric vehicle (EV) market is exploding in demand and mainstream adoption as governments push for fuel economy improvements and automotive companies look for new market opportunities. According to Forbes, “by 2020, EVs are likely to cost the same as conventional fuel powered equivalents.” Major manufacturers – like General Motors, Toyota, and BMW – plan to release “a mouthwatering potential of 400 models and estimated global sales of 25 million by 2025.” For EV design engineers and purchasing agents, this drive towards increased electrification results in the challenge of finding cutting-edge components that can handle increasing temperatures, voltage, and power without sacrificing reliability, availability, and footprint.

Multilayer ceramic capacitors (MLCCs) are commonly used in EV electronics and subsystems because of their high temperature ratings, tiny size, and easy surface mount form factor. In order to help you choose the right automotive-grade capacitors for your EV project, this whitepaper discusses the key considerations and certifications for EV components, common use cases in EV subsystems, and capacitor requirements for specific applications.

Choosing the right MLCC for your automotive application involves researching specifications, certifications, pricing and availability, and many other considerations.

Requirements For Automotive-Grade Capacitors

MLCCs are one of the key building blocks of control electronics, but in order to qualify for the EV market, they must meet specialized requirements. Important areas of consideration include:

- High Voltage: EV systems are based on high-voltage battery systems, so capacitors must be rated for increased ranges such as 250V to 400V for plugin hybrid electric vehicles (PHEVs), 800V for commercial vehicles, and 48V for hybrid electric vehicles (HEVs).

- High Power: In order to complete with combustion engine petroleum-based vehicles that are refilled within minutes, companies are focusing on ultra-fast charging solutions, including EV systems that can handle increasing amounts of power (greater than 3.3kW) and charge directly from the grid.

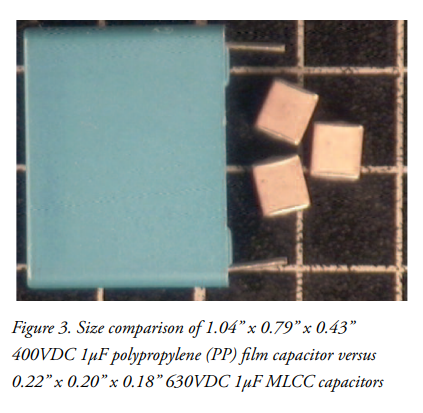

- Reduction in Size: The vehicle’s size and weight will affect its overall energy efficiency, so footprint reduction for EV subsystems (and the components they use) is a priority. Capacitors must therefore provide the same high performance within smaller dimensions.

- High Temperature: By pushing the boundaries with increased voltages, higher converter frequencies, and smaller footprints as mentioned above, all of these factors combine to create a high temperature environment that can be inhospitable to standard parts. Components must be rated to withstand and smoothly perform in those conditions.

- Industrial Reliability: Automotive-grade capacitors are designed to meet stringent standards of robustness, and special features have been developed for the most demanding applications that require increased reliability and superior mechanical performance.

With regards to specific certifications, the parts manufacturers you work with should be IATF 16949-certified. Published by the International Automotive Task Force (IATF), this technical specification for quality management establishes company-wide policies, processes, and documentation requirements for the automotive supply chain. IATF 16949 ensures that certified parts manufacturers meet an optimal level of quality when producing automotive grade components for Tier 1 suppliers and OEMs.

Another essential prerequisite is compliance with the AEC-Q200 Stress Test Qualification for Passive Components, as determined by the Automotive Electronics Council (AEC) Component Technical Committee. By subjecting capacitors to rigorous thermal, mechanical, and other stress testing, the standard raises the bar for automotive versus standard capacitors. Poor mechanical design and material selection can result in component failure and short circuits, so AEC-Q200-qualified MLCCs are specifically built with a focus on reliability and robustness to function even in the harshest automotive environments. Check out Table 1 for information on periodic AEC-Q200 tests conducted on Knowles Precision Devices (KPD) automotive-grade capacitors.

Common MLCC Use Cases In Electric Vehicles

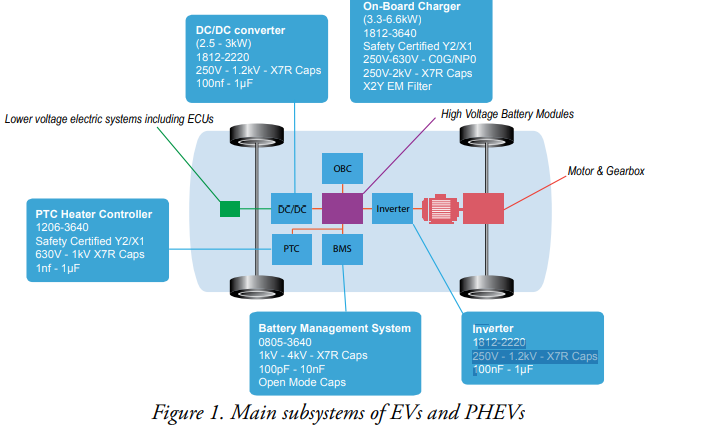

Now that the universal conditions for automotive grade MLCCs have been discussed, let us consider the specific capacitor requirements for the major electrical subsystems in an EV. Figure 1 provides a visual overview of the five subsystems that will be discussed, as well as the types of MLCCs commonly used in each area.

Battery Management System (BMS)

The goal of the BMS is to monitor and control the cells within a high-voltage battery stack. Primary functions include:

- Monitoring the battery cells’ voltage, current, temperature, and overall condition

- Providing diagnostic data for the battery

- Managing the current among cells (also known as cell balancing)

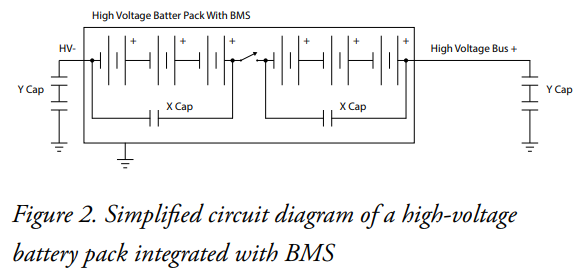

- Protecting the battery from over or under charging Safety Certified capacitors are commonly used at the input and output of major functional blocks (like the BMS) to help suppress the effects of electromagnetic and radio frequency interference (EMI/RFI). As seen in Figure 2, Class Y safety capacitors at the high voltage bus and Class X safety capacitors for each cell module are added for protection from EMI noise disturbance. Plus, they can offer electric leakage protection of high-voltage systems via insulation resistance monitoring with an RC circuit.

Class X and Class Y capacitors are mostly commonly available as ceramic or plastic film RFI/EMI suppression capacitors. However, given the high temperature and tiny size requirements for this subsystem, MLCC is the only viable option that will not melt away in BMS operating conditions. At Knowles Precision Devices, the MLCCs our customers typically use in BMSs include:

Class X and Class Y capacitors are mostly commonly available as ceramic or plastic film RFI/EMI suppression capacitors. However, given the high temperature and tiny size requirements for this subsystem, MLCC is the only viable option that will not melt away in BMS operating conditions. At Knowles Precision Devices, the MLCCs our customers typically use in BMSs include:

- 0805-1210 1kV-2kV 100pF-10nF X7R (2R1) capacitors (option for open mode)

- 0805-1206 50V-100V 15nF100nF X7R capacitors (options for open mode or tandem)

- 2306-2220 1kV-4kV 100pF-10nF X7R capacitors (options for safety certified and open mode)

- 2220 630V 1µF X7R capacitor

On-Board Charger (OBC)

On-Board Charger (OBC)

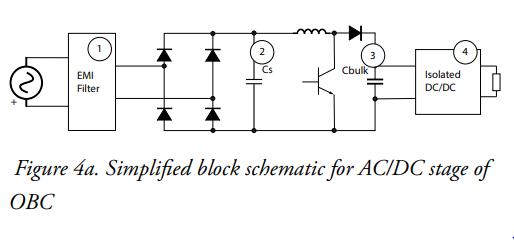

The purpose of OBC is to the charge the traction battery, usually in a range of 48V to 800V. Functions of the OBC include:

- Converting alternating current (AC) from the electric grid into direct current (DC) that charges the vehicle’s battery

- Providing power factor correction (PFC) to shape the input current to a power supply, maximizing efficiency and reducing harmonics

- Adjusting the produced DC voltage up or down to provide the correct DC levels to the battery

It is worth noting that manufacturers are now offering bi-directional OBCs that can take and convert residual power from the vehicle battery and feeding it back to the grid. As a result, higher MLCC components counts are used in bi-directional OBC.

It is worth noting that manufacturers are now offering bi-directional OBCs that can take and convert residual power from the vehicle battery and feeding it back to the grid. As a result, higher MLCC components counts are used in bi-directional OBC.

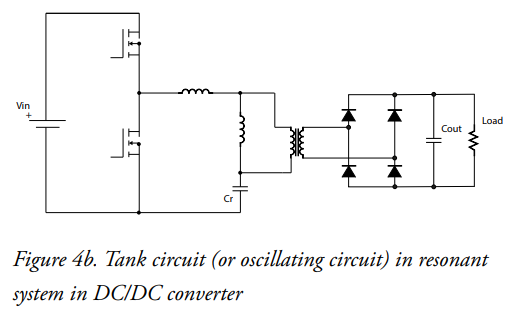

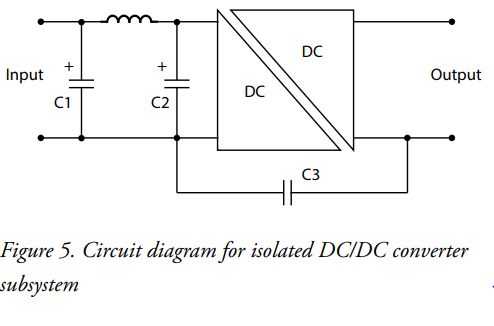

DC/DC Converter

In electric vehicles, the DC/DC converter subsystem is required to transfer energy between the high voltage battery and low voltage (e.g., 12V) systems. The vehicle’s high voltage system supplies large loads like the traction motor, air conditioner, and starter. The lower power system is used for components like infotainment systems, sensors, and safety. Figure 5 and Table 3 show two types of capacitors commonly seen in DC/DC converters:

As with the BMS subsystem, ceramic capacitors (instead of film capacitors) are advised to withstand the high operating temperatures of the DC/DC converter.

As with the BMS subsystem, ceramic capacitors (instead of film capacitors) are advised to withstand the high operating temperatures of the DC/DC converter.

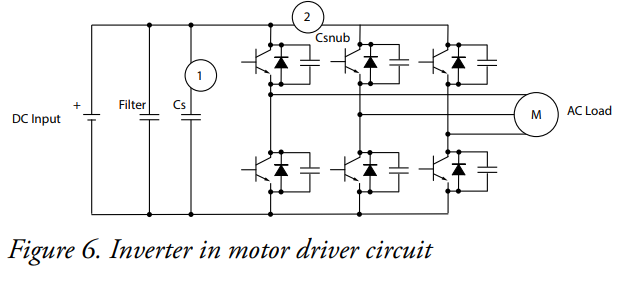

Inverter

Inverters convert DC power from the battery to threephase AC power to drive the traction motors. Important performance metrics for inverter systems include power handling capabilities, efficiency, reliability, and thermal performance. Typical motor control functions include:

- Converting from DC to AC during acceleration and AC to DC during braking

- Driving the insulated-gate bipolar transistor (IGBT) power stages

- Detecting the speed and position of the motor

- Diagnosing and managing potential issues to avoid inverter breakdown

Positive Temperature Coefficient (PTC) Heater Controller

Unlike petroleum-based cars that can warm the cabin using the combustion engine’s waste heat, EVs use high voltage PTC heaters as the heat source in the heating, ventilation, and air conditioning (HVAC) system. Not only do PTC heaters provide a comfortable cabin environment for passengers, but they maintain optimal operating temperatures for the batteries, allowing them to properly start and charge the car in cold weather. PTC heaters utilize specialized materials that, when cold, have lower electrical resistance, allowing full current to flow and heat to be generated. As the temperature increases, the resistance of the PTC material also increases. This property acts as an automatic safety feature that limits the current flow and prevents overheating. Common capacitors in this subsystem include:

Considerations For Choosing An MLCC Supplier

Not only is choosing the right capacitor important, but you also need to choose the right supplier who truly understands high voltages in the electric vehicle space. Automotive experts are accustomed to 12V or 24V applications, whereas EVs deal with medium to high voltage from 250V to as much as 800V systems. An experienced supplier can help advise you very early in the research and design process to avoid costly mistakes like flashovers and current creepage.

With more than 200 years of combined knowledge and expertise, Knowles Precision Devices is the premier global source for Syfer, Novacap, Dielectric Laboratories (DLI), and other name-brand capacitors. We have a long heritage of helping clients with mission critical applications – such as automotive, military/ aerospace, and medical devices – that must have high end performance and superior reliability. Our team of experts are ready to help you solve tough engineering challenges, find components that meet demanding specifications, and deliver products and solutions with short turnaround time. Our AEC-Q200-qualified MLCCs are uniquely positioned for the automotive EV market because we offer the broadest range of high-voltage, high capacitance, and small-size ceramic capacitors. With our unique wet process manufacturing technique, we can provide some of the fastest lead times in the industry and high flexibility for supporting urgent demand. Talk to us about your applications and find out how we can help you choose the right capacitor for your project.