Internet of Things (IoT) and the Industrial Internet of Things (IIoT) are rapidly changing the landscapes in the consumer electronics and industrial spaces respectively. With every passing day, we are seeing increasingly ‘smart’ devices like smart phones, consumer electronics, smart wearables etc. enter the markets.

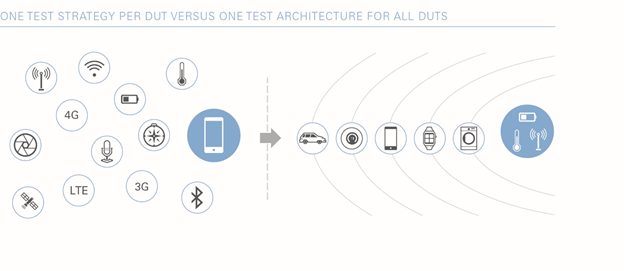

These ‘Smart’ devices are posing a challenge for the test engineers because they often include a wide-variety of sensors, support a host of wireless and connectivity standards, leverage software and hardware computing while operating on low/ultralow power consumption. Typical test managers today are seeing IoT from a device-under-test (DUT) – centric view. From this vantage point, the IoT can easily seem like an insurmountable 50-billion device challenge for any test organization. The need to test the infinite permutations of sensor, battery, computation and communications technology in devices both large and small against frequent software updates requires a ‘smarter’ approach.

The ‘Smarter’ approach to testing smart devices involves viewing these devices as ‘systems of systems’ or ‘super-systems’ based on a few core elements around a core architecture. By adopting a test strategy with an architecture-centric perspective, test organizations will be prepared to meet the challenges and opportunities of the IoT and will be well positioned to capitalize on the expected $19 trillion business opportunities it represents.

Survival of the Smartest

The three core elements of most smart devices are battery power, wireless connectivity, and sensors. Be it a smart thermostat, fitness tracker, or smartphone, the ‘smart’ devices of tomorrow will always have sensors for interacting with the world around them, a rechargeable battery for untethered operation, and various modes of wireless connectivity to send and receive information from the Internet and other devices around them.

Instead of designing a unique test system for each unique DUT, test leaders must design a smart test system that can adapt to and test all smart devices. Mino Taoyama, vice president of manufacturing, operations, and quality at Intel Corporation, and his team are tackling this problem head on. “With wearables, choice is a necessity because not everyone has the same taste in style,” he said. “However, when testing wearables, choice results in a high degree of product mix. At Intel, a single manufacturing line might produce thousands of different models of a fashion product in a year. The high mix requires that test systems be flexible enough to test a wide range of products and transition between them quickly. Our test systems are designed to handle a superset of the test needs of any one product—from supporting multiple wireless standards to mixed-signal testing.”

Testing a sensor requires the ability to reproduce physical stimuli often with other types of sensors or transducers. Testing a battery requires the ability to source, sink, and measure power. Testing wireless communication requires the ability to both generate and analyze RF signals. Add up this laundry list of functionality and it’s not hard to imagine a fully stacked, incredibly expensive rack of instrumentation. But thanks to Moore’s law, test instrumentation can now benefit from the same embedded technology that’s flooding the market with smart devices of all shapes and sizes.

NI offers modular hardware and software platforms that seamlessly integrate and provide the test engineers with the flexibility of software designed test instruments while leveraging the advances of Commercially-of-the-shelf (COTS) technologies. NI’s PXI portfolio includes IOs ranging from DC to millimeter wave; high-throughput data transfer bus based on Gen 3 PCI Express bus interfaces; sub nanosecond synchronization with integrated timing and triggering; the power and productivity of the LabVIEW and TestStand software environments. Test Engineers looking to leverage the PXI platform, also have access to a vibrant ecosystem consisting of over 300,000 users, 10,000 instrument drivers and 1,000 partners. The vast library of third-party software available through the LabVIEW Tools Network and from other resources available within the ecosystem allows test organizations to build these next generation test systems faster.

Driven largely by the Internet of Things (IoT) and the explosion of wireless standards, wireless has become usual on connected devices. NI creates fast and cost-effective wireless test solutions that help you to design innovative and high-quality products. NI solutions simplify parallel test, shorten test times, and reduce test cost. NI test solutions span from conformance to high-volume manufacturing and from 5G to 802.11ax to near field communication (NFC) and wireless charging.

The NI vector signal transceiver (VST) is designed for fast and accurate testing of a wide range of wireless devices, including WLAN access points, cellular handsets, and infotainment systems. Featuring a user-programmable FPGA and revolutionary RF measurement performance, the VST delivered unprecedented speed and insight in a single PXI device at an exceptional price. Not surprisingly, it rapidly became the best-selling PXI instrument ever while redefining RF instrumentation in the process. In the years since the VST introduction, NI has provided the power and flexibility of software-designed instrumentation to new instrument types and automated test applications. Meanwhile, Moore’s law and the big bang of smart devices proved that the software-designed instrument paradigm is the only paradigm that can sustain the pace of change because of its ability to evolve at the speed of software.

Take wireless for example. RF test instruments will require wider bandwidths to test future standards like 5G. Multiantenna and MIMO technologies require modular and flexible instrumentation that can scale from testing single-antenna devices to 8×8 MIMO devices and beyond. Finally, with wireless radios expected to cost a fifth of what they do today, future test equipment must be able to dramatically reduce the cost of test.

To exemplify ‘smarter’ and to provide unrivaled performance that meets both the current and scales for future requirements, NI launched the second-generation VST i.e. NI PXIe 5840. With 1 GHz of instantaneous bandwidth, it’s ideally suited for a wide range of applications including 802.11ac/ax device test, mobile/IoT device test, 5G communications design and test, RFIC test and radar prototyping. And though it features wider bandwidth, better measurement performance, extended frequency range, even more instrumentation capability and a larger FPGA for more advanced customization and signal processing, one thing hasn’t changed: engineers’ ability to make it whatever they need it to be.

For wireless production test environments, the NI Wireless Test System (WTS) provides a highly flexible multisite automated test system built on the NI PXI platform and the Vector Signal Transceiver technology. NI WTS is a multi-port, multi-DUT, multi-standard solution for accurate yet extremely fast production testing of wireless devices. This system includes one or more RF vector signal analyzers and generators, and robust N-type DUT connectors to simplify connectivity for manufacturing test environments. NI WTS can be used in applications such as testing of WLAN access points, cellular handsets, infotainment systems, and other multi-standard devices that include cellular, connectivity, and navigation standards.

The latest release 1.3 of the WTS includes support for 8×8 multichannel configurations and custom 802.11ax test steps with device under test (DUT) control for efficient parallel test of new connectivity devices based on the IEEE 802.11ax draft standard (Draft 1.1). Additionally, release 1.3 of the WTS improves parallel test of Bluetooth 5 and low-power Internet of Things (IoT) standards, such as ZigBee and Z-Wave.

The new 802.11ax draft standard includes significant changes to the physical layer (PHY) to deliver higher average data throughput per user in crowded environments. These changes introduce more complexity to characterization, design validation and production test efforts, but engineers can take advantage of the WTS to automate their 802.11ax measurement solutions for accurate and extensive test coverage of their new designs. The WTS instrument software and NI’s vector signal transceivers (VSTs) power large multiple input, multiple output (MIMO) setups up to 8×8, dual-band simultaneous test and accurate error vector magnitude (EVM) measurements. The new software also addresses the difficult task of creating a variety of trigger-based multiuser scenarios in which each simulated user has unique waveform settings and impairments. To shorten development time in the presence of these new test challenges, the WTS provides built-in support for DUT control tools from leading chipset vendors.

“The rapid pace of change in modern wireless standards combined with constant market pressure to lower test cost demands smarter test systems,” said Charles Schroeder, vice president of RF marketing at NI. “A test solution – like the WTS – that is optimized for rapid, multi-DUT execution based on flexible software and modular hardware, helps provide significant cost, yield and future-proof advantages.”

The WTS presents an efficient and robust platform for multisite test of the latest 802.11ax, Bluetooth Low Energy and low-power IoT devices. This approach systematically scales with the evolving RF requirements of wireless standards to lower the cost of test, increase production output and future proof testers for tomorrow’s challenges.