Introduction: A load cell is a force transducer. It converts a force such as tension, compression, pressure, or torque into an electrical signal that can be measured and standardized. As the force applied to the load cell increases, the electrical signal changes proportionally. The most common types of load cells used are strain gauges, pneumatic, and hydraulic.

Strain-gauge load cell

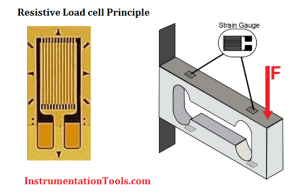

Although there are many varieties of force sensors, strain gauge load cells are the most commonly used type. Except for certain laboratories where precision mechanical balances are still used, strain gauge load cells dominate the weighing industry. Strain gauge load cells offer accuracies from within 0.03% to 0.25% full scale and are suitable for almost all industrial applications. Strain gauge load cells contain strain gauges within them that send up voltage irregularities when under load. The degree of voltage change is covered by digital reading as weight.

Strain gauge load cells are a type of load cell where a strain gauge assembly is positioned inside the load cell housing to convert the load acting on them into electrical signals. The weight on the load cell is measured by the voltage fluctuation caused in the strain gauge when it undergoes deformation.

The gauges themselves are bonded onto a beam or structural member that deforms when weight is applied. Modern load cells have 4 strain gauges installed within them to increase the measurement accuracy. Two of the gauges are usually in tension, and two in compression, and are wired with compensation adjustments.

When there is no load on the load cell, the resistances of each strain gauge will be the same. However, when under load, the resistance of the strain gauge varies, causing a change in output voltage. The change in output voltage is measured and converted into readable values using a digital meter.

What is the function of the load cells?

A load cell is a transducer that converts the mechanical force into readable electrical units, similar to our regular weighing scales. Their main purpose is to weigh or check the amount of load transferred. The load cell sensors are always bonded along with elastic material, known as strain gauges.

What is load cell used for

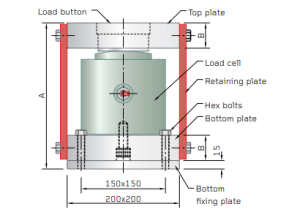

The type of instruments used in the geotechnical field depends on the scope of work. Load cells can be used at the initial stage i.e. during the research and development or even at a later stage while monitoring a structure.

Geotechnical instruments are used both pre and post-construction to ensure the safety of structures, dams, tunnels, bridges etc. Proper geotechnical monitoring ensures the long-term safety of these structures.

Load cells find their application in the geotechnical field and, they are commonly used to monitor:

- Deep foundations: excavation bracing like struts, soldier pile; tiebacks or anchors; retaining walls

- Tunnels and shafts: Steel liner plate, cast-in-place concrete, segmented precast concrete, shotcrete

- Dams: Concrete Dams, Underground Power House

- Piles: Pile load test

Why load cells are used?

A load cell is a type of transducer which is used to convert mechanical force into a measurable electrical output, anything which needs to be weighed probably uses a load cell to do so. Load cells come in many different shapes and sizes so that they can be added to different machinery and weighing equipment.

What is load cell working principle?

When a load, force, stress is applied to the sensor, it changes its resistance. This change in resistance leads to a change in output voltage when an input voltage is applied.

There are many different kinds of load cells.

Resistive load cells work on the principle of piezo-resistivity. When a load, force, stress is applied to the sensor, it changes its resistance. This change in resistance leads to a change in output voltage when an input voltage is applied.

Capacitive load cells work on the principle of change of capacitance which is the ability of a system to hold a certain amount of charge when a voltage is applied to it. For common parallel plate capacitors, the capacitance is directly proportional to the amount of overlap of the plates and the dielectric between the plates and inversely proportional to the gap between the plates.

What is load cell and its types?

Load cells are a type of sensor which are used to measure force and load. They convert the force into an electrical signal. Many load cells use internal strain gauges in order to do this. The strain gauges react to the compression and the change in resistance results in a change in output.

Load Cell Types and Applications

Single Point Load Cells: Single point load cells are the most common type of load cell available on the market today. They are often hermetically sealed. They have the ability to measure off-centre loads which is useful for building scales, they offer high reliability and high accuracy. Single point load cells are often used in low capacity compact weighing systems.

Applications of Single Point Load Cells: As one of the most diverse load cells, single point have many applications; Counting scales, balances, bag fillers, retail, medical weighing, packaging, pricing scales and industrial weighing.

S-Type Load Cells: S-Type load cells take their name from their shape. They give excellent performance in both tension and compression applications. They offer high endurance, compact designs making them suitable for tight environments. Many S types also have an option for ATEX approval making them suitable for hazardous conditions.

Applications of S-Type Load Cells: Applications for S-Type load cells include; hoppers and truck scales, tank level scales, mechanical to electrical scales conversions, level and inventory monitoring.

Tension/Compression Load Cells: Most load cells can be referred to as Compression Load cells so this type is vast. They are compact cells with the ability to carry high capacity loads and are known for being highly accurate. They are particularly well suited to industrial applications where reliability is required.

Applications of Tension/ Compression Load Cells: Compression load cells are widely used for platform scales, hopper scales, automobile testers, track scales and electronic weighing devices.

Shear Beam and Bending Beam Load Cells: Bending beam load cells often offer low profile construction and can be integrated into restricted areas. They are very cost-efficient and some models are corrosion resistant and well suited to harsh environments.

Applications of Shear Beam and Bending Beam Load Cells: Bending beam load cells are well used for OEM applications and in multiple cell applications such as tank weighing and industrial process control. They are also well used in force measuring applications, static weight and dynamic weighing.

Miniature Load Cells: Miniature and subminiature load cells are small in size with a low profile design – some of them are less than 1cm in height. This makes them well suited to applications where space can be an issue. Although they are small they are still rugged and highly reliable.

Applications for Miniature Load Cells: Test benches, industrial weighing applications prototype structures.

Strain Gauge Load Cell, S type, 5kg/50kg/1000kg/3 ton to 20 ton: S type load cell can bear both tension and pressure, with good output symmetry, high accuracy, compact structure and complete specifications. Strain gauge load cell can be applied for batching scale, electronic-mechanical scale, crane scales and other force value measurement and control.

Tension and Compression Load Cell, 100kg/2 ton to 20 ton: Tension and compression load cell can bear both tension and pressure, with good output symmetry, high eccentric load resistant, compact structure and complete specifications. Strain gauge load cell can be applied for batching scale, crane scales and other special weighing instruments.

Tension/Compression Load Cell, Low Profile, 500kg/30 ton to 100 ton: Low profile load cell also known as pancake load cell, has flat design, high strength and good symmetry. Tension and compression load cell can be applied for platform scale, truck scale, rail weighbridge and material level measurement and control in warehouse, with good anti-eccentric load performance, low height, all sealed structure and complete specifications.

Shear Beam Load Cell for Rail Weighbridge/Truck Scale, 10/20/30/50 ton: Shear beam load cell has a combined indenter for automatic resetting and self-aligning, with strong anti-eccentric load capability and easy installation. Shear beam load cell is suitable for rail weighbridge, truck scale and various electronic scales.

Digital Load Cell Amplifier, Output 4-20mA/0-10V/RS485: High precision load cell amplifier has a 6 digit LED display, output signal 4-20mA/ 0-5V/ 0-10V/ RS485. There are 3 keys for parameter settings. Digital load cell amplifier can be calibrated on-line by its 3 keys. The setting parameters include zero, capacity, communication rate, division value, decimal digits, etc.