Courtesy: Lam Research

- AI’s evolution could be thwarted by electrical resistance in 3D architectures

- Molybdenum, a breakthrough material, reduces resistance, improves performance

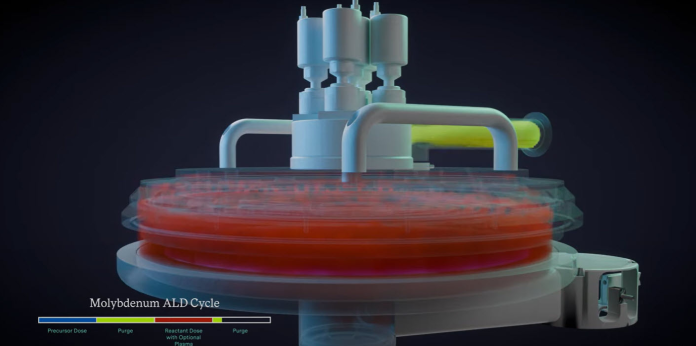

Lam Research’s ALTUS Halo is designed to address the unique challenges of molybdenum implementation in leading-edge integrated circuit types.

The AI revolution faces an invisible barrier: electrical resistance. As artificial intelligence (AI) demands ever-increasing compute, the semiconductor industry has responded by building upward, creating dense 3D architectures that pack more computing power into each square millimeter.

But this vertical scaling creates an unprecedented engineering challenge: every electrical connection through these towering structures must be perfect at the atomic scale, or AI performance degrades catastrophically.

Advanced 3D Integration and Metallization Barriers in AI Chip Manufacturing

Traditional metallization approaches are reaching their physical limits.

In conventional chip designs, creating electrical pathways meant depositing metal into dielectric etched features. These methods relied on barrier layers (e.g., titanium nitride, TiN) to prevent unwanted interactions between metals and surrounding materials.

While necessary, these barriers add electrical resistance—acceptable in simpler chips, but a fundamental roadblock in 3D architectures where signals must (soon) travel through up to 1,000 NAND layers of vertical connections.

The narrowing of lines caused by device shrinking drives the need for new materials with shorter mean-free paths—the distance electrons can travel before colliding—that match line length to achieve lower resistance.

The surge in compute demand compounds the challenge. Every suboptimal connection, every additional barrier layer, creates performance bottlenecks and thermal management challenges that can degrade overall AI system capability.

Molybdenum Innovation Provides a Breakthrough Material for Advanced AI Chip Architecture

Lam’s leadership in metallization innovation spans decades of industry inflections. Our pioneering work with tungsten atomic layer deposition (ALD) enabled the revolutionary shift from planar to 3D NAND memory. Now, as device features continue to shrink, we’re driving another fundamental transition with molybdenum—a material uniquely suited for today’s confined spaces.

Molybdenum (Mo) emerges as a transformative material for advanced metallization because its shorter mean-free path makes it uniquely suited for today’s confined spaces.

And unlike tungsten and other metals, Mo doesn’t need an adhesion or barrier layer (like TiN), simplifying the manufacturing process while significantly reducing overall resistance.

The transition to molybdenum echoes another historic industry inflection point: the shift from aluminum to copper interconnects in the early 2000s, which Lam led. Just as that transition fundamentally changed semiconductor manufacturing, today’s move to Mo represents a similar watershed moment.

Advanced ALD Solutions for AI-Era Chips

Material selection alone isn’t enough. Our latest innovation, ALTUS Halo, represents a convergence of atomic-scale engineering and practical manufacturing solutions. The platform brings specific innovations for each critical application:

- For 3D NAND it enables void-free lateral and barrier-less fill through advanced ALD technology and precise wafer temperature control.

- For DRAM applications it drives metallization innovation with selective and conformal fill capabilities.

- For logic it offers both thermal and plasma ALD options with an integrated interface cleaning process.

Atomic-Scale Engineering for AI Computing

The implications extend far beyond material selection and manufacturing processes.

Lam’s advances in deposition technology and grain engineering enable optimal molybdenum integration across all leading-edge applications—from 3D NAND wordlines to advanced logic interconnects and DRAM structures.

Initial atomic layers in ALD are critical for interface engineering and subsequent film growth, serving as the template for the material’s properties. The ALTUS Halo quad station module architecture is ideal for creating the most advanced fill processes with the highest productivity due to its flexibility of running different wafer temperatures, process steps and chemistry at each station.

As the industry pushes toward increasingly complex architectures, this precision engineering at the atomic scale becomes even more critical.

A Semiconductor Industry Transformation in Memory and Logic

The semiconductor industry stands at a crucial juncture. Data-intensive AI applications demand significant advancements in both memory and logic technologies. These next-generation devices require unprecedented precision in metallization, where even small improvements in resistance and thermal performance can have outsized impacts on overall system capability.

Through innovations like ALTUS Halo, Lam is enabling a fundamental transition across NAND, DRAM, and logic. As the semiconductor industry pushes physics and chemistry to their limits, our manufacturing-ready solutions will help define the future of AI computing.