Meaning and definition of a thermistor

The word ‘thermistor’ is a combination of two words ‘thermal’ and ‘resistor’. The word ‘thermal’ means ‘heat energy’ which is measured as temperature, whereas ‘resistor’ means ‘an equipment that obstructs the flow of electricity, that is, current, both direct and alternating’.

Put simply, a thermistor is a temperature-sensor that measures temperature with respect to change in resistance. It so happens because it is made up of a semi-conducting material that exhibits a ‘precise and large’ change in resistance with respect to a small change in temperature.

Since it is made up of a semi-conducting material, it exhibits resistance intermediate between the resistance of conducting and insulating materials.

Furthermore, the relationship between the variation of a thermistor’s resistance with respect to temperature is dependent upon the ‘resistance-coefficient’ of the semi-conducting material used to make a thermistor. Either it can be positively-related or negatively-related.

Even though both thermistor and resistance temperature detector (RTD) measure temperature with respect to change in electrical resistance, they are different!

This difference is based on the material used to construct them and the temperature range over which they are used. The former uses metallic oxides and operates at fairly low temperature range, whereas the latter uses pure metal and operates at high temperature range.

Components of a thermistor

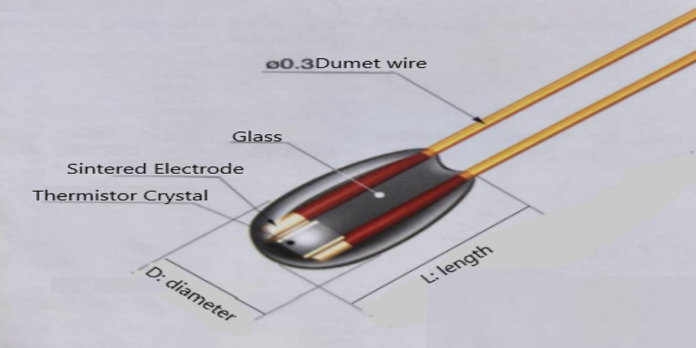

A thermistor is composed of two wires that are connected to a semiconducting material. All these are pressed into a disk, cylindrical shape, or bead, and then compressed inside an impermeable material, for instance, a glass.

This semi-conducting material is made up of a wide range of materials depending upon the requirement. It is then connected to an ohm-metre. The latter measures the change in resistance of the semi-conducting material.

Although the semi-conducting material of a thermistor is usually made up of either transition metal oxides, such as, oxides of manganese and nickel, or perovskite crystals, such as, strontium titanate and lead (II) titanate, nowadays, it is also made up of cement-based material, conductive polymers and graphene.

Working principle of a thermistor

A thermistor functions based on the movement of electrons or lattice aggregate with respect to change in temperature and the Steinhart–Hart equation.

This equation gives the relationship between resistance of a semi-conducting material and temperature. With this equation, for any specific semi-conducting material, the change in resistance with respect to change in temperature, and vice-versa, can be computed.

Besides, over a temperature range of 200 °C, the error in computation from the Steinhart–Hart equation is less than 0.02 °C. Hence, it yields a highly accurate temperature measurement.

When a thermistor is put at a point where temperature is required to be measured, due to thermal energy at that point, either the valence electrons from the lattice atoms are loosened or the thermal lattice agitations changes. This leads to change in resistance of the semi-conducting material based on its resistance-coefficient. When this change in resistance is measured and then applied in the Steinhart–Hart equation, it yields the temperature at that point.

Types of thermistors

Thermistors are classified based on the basis of the ‘resistance-coefficient’ of the semi-conducting material that makes up a thermistor. They are of the following types-

First, negative temperature coefficient thermistor. In this type, the resistance of its semi-conducting material is negatively related to temperature, that is, the resistance decreases with an increase in temperature.

It so happens because with a rise in temperature, the valence electrons from the lattice atoms are loosened. As these electrons move, they transport electricity more easily. Hence, the resistance decreases.

The material used to make a negative temperature coefficient thermistor is decided based on the temperature range required to be measured. For instance, germanium measures temperature in the range of 1 Kelvin to 100 Kelvin, whereas silicon measures temperature upto 250 K.

On the other hand, the metallic oxides measure temperature in the range of 200 K to 700 K. Hence, to measure higher temperature ranges, thermistors are manufactured using oxides of beryllium, yttrium, zirconium, dysprosium, aluminium, etc.

Second, positive temperature coefficient thermistor. In this type, resistance of its semi-conducting material is positively related to temperature, that is, the resistance increases with an increase in temperature.

It so happens because with rise in temperature, there is an increase in the thermal lattice agitations, particularly those of impurities that are used to dope the semi-conducting material. This obstructs the flow of electricity. Hence, the resistance increases.

A positive temperature coefficient thermistor is of two types-

One, switching positive thermal coefficient thermistors. These thermistors show a non-linear relationship with change in temperature.

As a result, initially, the resistance decreases minutely with a rise in temperature. But, once a critical temperature, known as Curie temperature, is reached, the resistance rises rapidly with rise in temperature. Hence, they are ideally suited for protective applications.

Two, silistor positive thermal coefficient thermistors. These thermistors show a linear relationship with change in temperature. Resultantly, the resistance increases with a rise in temperature.

Among all the thermistors, the negative temperature coefficient thermistors are the most widely used.

Benefits of using a thermistor

There are numerous benefits of using a thermistor. They are as following-

First, they are ideally suited for detecting small changes in temperature. It is so because they have higher sensitivity and shorter response time. In fact, they are the most accurate temperature-sensors.

Second, their cost of production is low. Hence, they can be produced en masse at a low cost.

Third, chemically, they are highly stable and not significantly affected by aging, that is, use over a reckonable period of time.

Limitations of using a thermistor

Besides having numerous benefits, there are few limitations of the use of thermistors. Few of them are as enumerated below-

First, they function over a limited temperature range, mostly between 0°C to 100°C. However, with new advances in technology, the temperature range of functioning of a thermistor has increased. However, due to relatively high cost of production involved in the large-scale production of the latter, most thermistors produced are functional within the stated range.

Second, they work only up to 50°C of the base temperature.

Applications of thermistor

Depending upon the benefits and limitations of the use of thermistors, they are used in as following-

First, since thermistors are ideal for detecting small temperature changes, they are used in an array of temperature-measuring devices. For instance, hair dryers, refrigerators, freezers, toasters, etc., use thermistors for accurate temperature sensing.

Second, they are employed to measure radio-frequency power and radiant power. For instance, infrared and visible light.

Third, they are used in myriad electrical circuits for two purposes. One, to compensate for changes in temperature of the other components. And, two, to detect overload and thus prevent any further flow of electric current in the circuit.

Fourth, they are used in mobile phones to keep a watch on the temperature of different components and relay data to the integrated circuit about it.

Fifth, they are used in microwaves to prevent it from overheating and catching fire.

Sixth, they are used in automobiles for measuring the temperature of different components, oil and coolant.

Seventh, they are used in washing machines to determine the optimum temperature for the operation of washer and dryer.

Eighth, they are used in lithium battery rechargers to stop further charging once the battery is fully charged.