Following the breakthrough with their first sweating artificial skin two years ago, Danqing Liu’s multidisciplinary team hasn’t been sitting still. Their goal: artificial skin that sweats as naturally as possible. There, they explain how they managed to be the first team in the world to be able to accurately control where, when and how much an artificial skin sweats and also where the liquid collects.

In the previous breakthrough by the team, it became apparent that an artificial skin that can sweat on command could have numerous practical applications. Back then, the artificial skin could secrete the fluid evenly and equally everywhere. An evenly sweating artificial skin can help cool the surface of robots. In social applications, it could help make the robot as human-like as possible, which includes sweating. Or consider special bandages that can deliver controlled drugs to human skin or to a wound surface such as a burn.

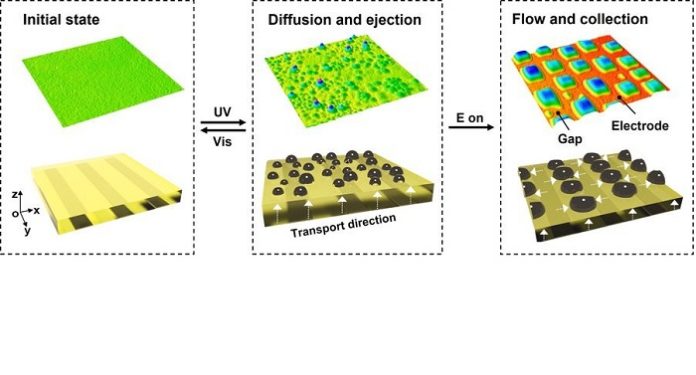

These applications will only become more tangible as this new invention allows them to control where the artificial skin excretes fluid within a few micrometers. Not only that, but the researchers now control how much and for how long the fluid is released by the artificial skin, as well as where the fluid collects and when it is time to reabsorb it.

The release of fluid is stimulated by UV light. By then applying a voltage to the underlying electrical grid, the fluid collects in the desired places. Through the clever design of the grid, this can be completely controlled and creates a very natural sweat pattern. Think about yourself: on a hot day, sweat also collects in specific places on your face. This artificial skin brings us a big step closer to imitating the natural behavior of the skin.

Multidisciplinary team

Danqing Liu, assistant professor at the department of Chemical Engineering & Chemistry and affiliated with the ICMS institute, and het postdoc YuanYuan Zhan’s drive and enthusiasm are infectious to anyone who speaks to her. In Liu’s special lab, she has gathered a unique multidisciplinary team around her. The lab also has the equipment to do electrotechnical, chemical and physical research in conjunction with industrial design, which is fairly exceptional within the university. Together, they are doing research on several promising materials based on liquid crystals, better known for LCD screens.

“It’s so cool to see what our team can accomplish with these materials based on outside stimuli!” Liu enthusiastically explains. “I have a very broad technical background, so I can brainstorm with each team member. Still, everybody’s specialisms were essential to achieving the results that we are now demonstrating.”

Unique combination of properties

What makes this new iteration of artificial skin by Liu’s team so unique is the far-reaching control that they have over the skin’s behavior: secreting, dispersing, or collecting and reabsorbing the liquid, a process which they control via free UV light and electricity. Unsurprisingly, their work is generating excitement in materials science.

“My motivation is to develop useful materials. I, therefore, like to start a project with a clear goal in mind. In this case, we’re looking for new material for a useful medical application,” says Liu. “And that takes time. It may seem like it’s now going quickly, but from the first inspired idea to where we are now this breakthrough has taken us over ten years. And we’re not done yet.

“We started with the idea of seeing what we could do with liquid crystals in soft robotics in 3D. The focus then shifted to a 2D robot skin. We were keen to complement traditional robotics rather than compete with it. With the skin, we found that we could control the topology (mountains and valleys at the micrometer scale).

“We could use that as a coating to shake the sand off of the Mars Rover’s solar panels, for instance. Another application we’ve worked out is alternating between sticky and non-sticky sections of the coating. By choosing which material is on the tops of the mountains and which is in the valleys, we could ensure that something is sticky or not. This could be a better method than a vacuum cup, especially for fragile or delicate parts like thin glass.”

And this brings us to Liu’s team’s current research. Together, they are working on that one dream: not simply imitating nature but helping it to evolve by adding to what is already possible. And it seems fair to conclude that they are succeeding in doing so with their unique liquid crystal materials.