Courtesy : Avnet

Asset tracking is an active IoT application area. It combines data collection, low power design and wide area communications.

Asset tracking is one of the most interesting IoT use cases. Offering the ability to track everything from a single consignment of urgent medical supplies through to a courier’s fleet of 1,000 delivery vehicles, asset tracking continues to grow in popularity.

This presents many commercial advantages and considerations. One is the number of potential applications. These range from tracking shipping containers across the world’s oceans to safeguarding lone workers in medical research establishments. The ability to track any asset in real-time, whether a person, goods or capital-intensive plant, significantly benefits any business.

Global just-in-time supply chains benefit from knowing everything about consignments of fresh produce, from when it leaves the supplier to where it is on its journey to the distribution center. This data is transforming business operations. Streamlining logistics operations is one aspect. Added benefits include logging the container’s temperature and humidity to validate it remained constant throughout the journey. Early access to these data can help ensure the produce arrives in perfect condition.

Asset tracking also presents many design challenges for embedded engineers. Given the diversity of potential applications, the first task is to outline the tracker’s specifications.

What is involved in tracking an asset?

Although the likely use case may require attention to a long list of criteria, the initial factors include how it will be powered, the location technology used, the operating environment, how it will communicate, and what data it will capture.

How will the tracker be powered?

In some cases there may be power available to the tracker, but it is more likely that it will be untethered. Typically, that means operating from a battery. Primary or secondary batteries require replacement, which can impact the user or service provider. Frequent service calls could result in labor costs many times greater than the replacement battery.

Combining a rechargeable power source with ambient energy harvesting techniques, such as a solar panel or thermoelectric device, is gaining popularity. Good design choices here can reduce the need for maintenance, making the asset tracker far more sustainable in the long-term.

Using a battery, whether replaceable or rechargeable, requires an ultra-low power design. Modern energy-efficient wireless microcontrollers are a good option. They combine control with communication in an optimized, integrated solution.

Geographic location requirements

What are you tracking, for how long and where? The tracker could be deployed globally. It may cross oceans, where connectivity is limited. It may be attached to a lone worker for safety purposes. This will influence the type of location resolution required.

Acceptable resolution may be a few miles at sea, but a few feet to track a person to a warehouse or buildings with multiple floors. These requirements will determine how the asset is geo-located and also shape the wireless communication chosen.

For a lone worker tracker, such as an overnight on-call service engineer covering multiple sites, global navigation satellite system (GNSS) location would be viable if the person is travelling between sites or outside. When inside, geo-location using Bluetooth beacons may be the better solution. Bluetooth geo-location methods require two or more beacons and antennas. They utilize angle of arrival (AoA) and time of arrival (ToA) techniques to triangulate the tracker with respect to a beacon in a fixed and known location.

Mechanical, environmental, and physical constraints

The use case will determine the tracker’s packaging. Does it need to be ingress protected and mechanically robust, or will a simple plastic enclosure suffice? A tracker attached to a multimodal shipping container must be robust enough to survive mechanical shocks, constant vibration and exposure to every environmental condition, from salt spray and dust to temperature extremes. However, it still needs to receive GNSS signals using either an internal or externally mounted patch antenna.

How will it communicate?

Many wireless protocols are available with the use case shaping the desired method. Bluetooth Mesh or ultra-wideband (UWB) may suit indoor tracking, and for global tracker deployment, 4G cellular with 2G and 3G fallback is desirable.

Within a warehouse, tracking individual pallet-based consignments, popular methods include near-field communication (NFC) and radio frequency identification (RFID) tags.

What data needs reporting?

In addition to obtaining the tracker’s location, typically using a multi-constellation GNSS receiver, what other sensor data is required? Temperature, humidity, shock/vibration, and battery voltage are just a few parameters that may need to be monitored.

The frequency of reporting impacts the tracker’s duty cycle and has a significant bearing on battery life. Keeping the data payload to a minimum and as frequent as strictly necessary can save energy. For example, the application could reduce the duty cycle such that it only sends measurements when something changes. Sending the location every minute of an asset tracker fitted to a delivery vehicle would be redundant when loading at a distribution center. The transmit profile can be optimized considerably by examining the real-world needs.

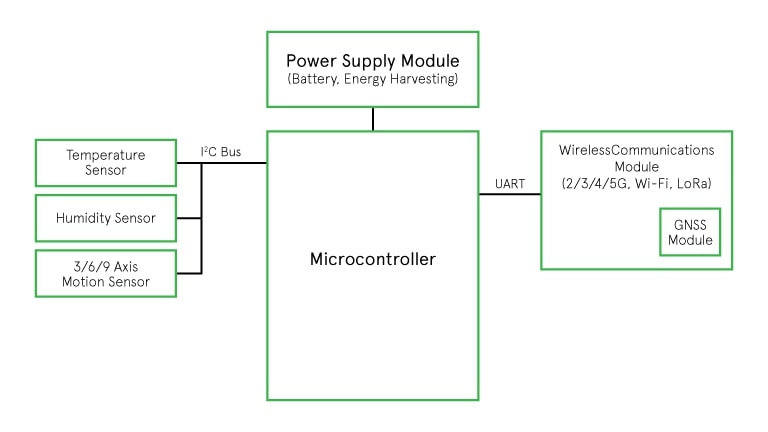

The architecture of a typical asset tracker

A typical architecture of a wireless asset tracker is shown below. The temperature, humidity and MEMS-based accelerometer (used to detect vibration and shock forces) are connected to the microcontroller (MCU) over an I2C interface. The communication and location modules often use UART interfaces. The MCU, sensors and modules should be placed into low power sleep modes (if available) between active cycles.

During an active cycle, the MCU wakes from a deep-sleep mode, reads the sensors and decides if it needs to send an update. If so, it will wake the communication and location modules, obtain location coordinates, and prepare the data packet for transmission. The data will be sent to a cloud-based tracking system, where it can be accessed by the operator or customer.

Many I2C-connected sensors are now available. Typically, these sensors incorporate custom logic that controls the sensor elements, normalizes the measurements, and places the data into I2C registers ready for collection. This integrated approach typically incorporates low-pass filters and other signal conditioning functions that remove unwanted noise and high-frequency artifacts.

Normally, the MCU can put the sensor core circuits into a deep sleep immediately after measurement, leaving only the I2C registers active.

Using a serial bus can simplify design and improve time to market. Rather than having to design the signal conditioning and conversion chain around an analog sensor element from scratch, the design team can quickly access and process sensor measurements.

A simple potential divider circuit provides a low-cost method of monitoring the battery voltage using an analog-to-digital converter (ADC) incorporated inside the MCU. Most microcontrollers offer at least one ADC, typically a 10-bit or 12-bit converter that is suitable for a wide variety of applications. A general-purpose input/output (GPIO) pin in series with the potential divider can also reduce the quiescent current drawn when not required.

Tracking assets, whether people, capital equipment or shipping containers, showcases the best of the IoT. An asset tracker incorporates the essential elements of embedded design with an ultra-low-power microcontroller, wireless connectivity, geo-location capabilities, and low-power sensor ICs. Asset trackers streamline supply chains, protect people and improve asset longevity.